Workshop Cleanup: FlowCore Protection for Plaster, Tile & Timber Dust

In This Article

- Workshop cleanup is essential for maintaining respiratory health and work efficiency.

- The FlowCore respirator system exceeds standard dust mask protection with its FFP2/FFP3 capabilities.

- Plaster, tile, and timber dust should be cleaned using specific surface and air techniques.

- Proper ventilation and HEPA vacuum systems are critical in any workshop environment.

- Follow manufacturer guidelines to replace FlowCore filters and maintain full efficiency.

- Investing in reusable PPE ensures both safety and long-term cost savings.

- Long-term exposure to fine dust has proven links to serious health conditions—take precautions seriously.

- Visit Learn more about Workshop Dust Protection and PPE Selection and Read a related article for product reviews and additional cleaning strategies.

Importance of Controlling Dust in DIY Workshops

Why dust from plaster, tile and timber poses a risk

Workshop cleanup is not simply about keeping a tidy space—it’s a matter of health and safety. Dust created from plaster, tile cutting, and timber sanding is far more hazardous than it may appear on the surface. These fine particles linger in the air, infiltrate your lungs, and can cause long-term respiratory conditions if left unmanaged. In DIY workshops, where appropriate industrial-level extraction and filtration systems may be lacking, the danger escalates significantly. Combined with poor ventilation, these particulates contribute to a toxic environment capable of causing silicosis, asthma, and other chronic issues.

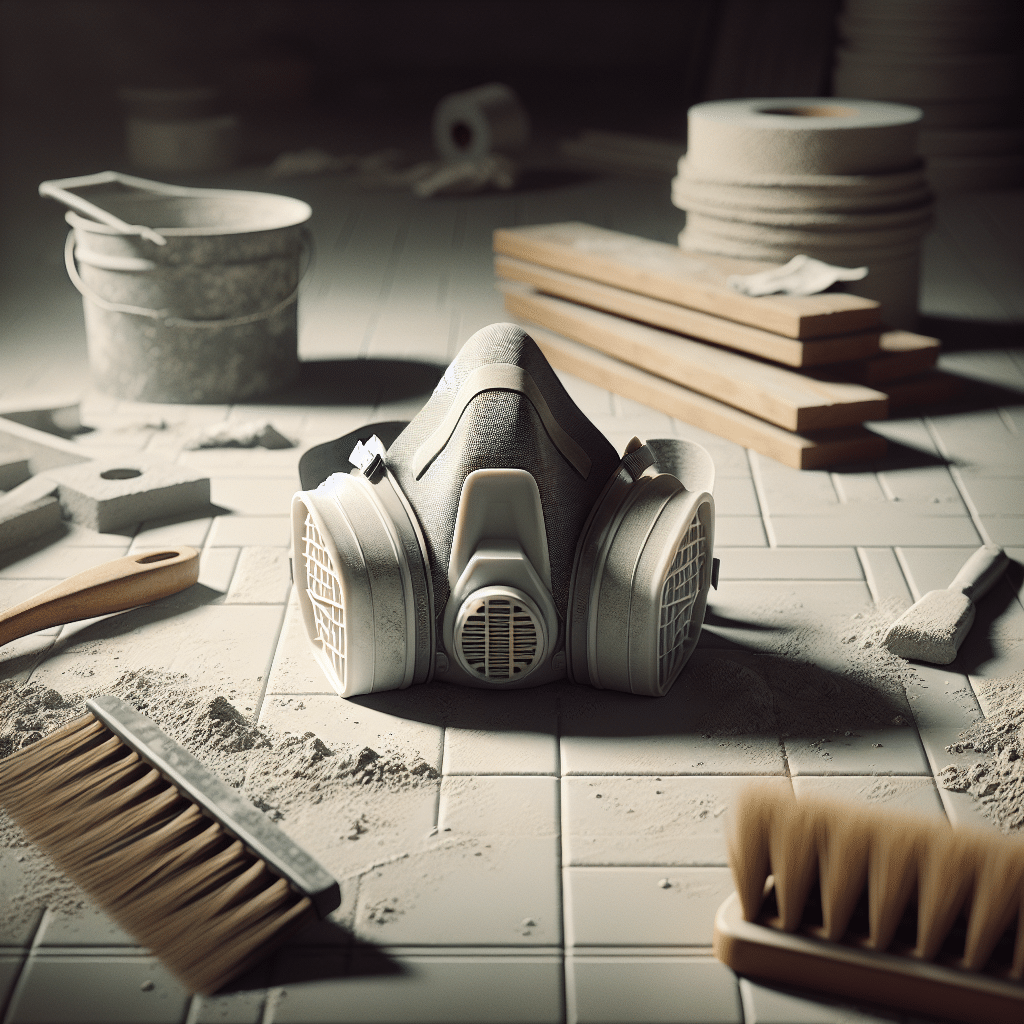

Understanding the FlowCore Respirator System

FFP2/FFP3 filters specifically for construction dust

The FlowCore respirator represents a crucial advancement in personal protective equipment for workshop environments. Engineered specifically for high-risk dust such as from plaster, tile grout, and timber sawing, this system integrates FFP2 and FFP3 filters—proven to capture up to 99% of airborne particles. These filters surpass basic mask standards, offering more comprehensive filtration without sacrificing comfort or breathability. Unlike standard dust masks, FlowCore systems provide a full-seal fit, ensuring contaminants do not bypass the barrier. Moreover, the unit is designed to distribute weight evenly across the head and neck, allowing for extended wear during lengthy DIY sessions.

“FlowCore changed the safety game in my home workshop—no more irritated lungs or cleanup dread.”

Workshop Cleanup Best Practices and PPE Tips

Successful workshop cleanup begins with proactive planning paired with the right protective equipment. First and foremost, always wear suitable personal protective equipment (PPE), including a FlowCore respirator. Safety goggles, gloves, and anti-static, puncture-resistant clothing should also be standard. Next is the micro-method: isolate areas where dust generation will occur. Plastic sheeting, temporary doors, and dust collection hoods help prevent spread to other work zones.

Schedule cleanup at regular intervals rather than waiting until the end of the project. Use HEPA filter vacuums, not household models, as DIY dust contains hard and abrasive particulates. Always vacuum before sweeping—sweeping alone simply redistributes particles. Combine ambient air purifiers with extraction fans to minimise airborne dust. Finally, maintain consistent filter checks on your PPE and vacuum systems to ensure optimal performance.

Cleaning Plaster Dust Without Recirculating Particles

Plaster dust poses a unique challenge. It is incredibly fine and frequently stays airborne for long durations. It also clings to surfaces due to static charge. Begin by wetting down surfaces using a spray bottle with water and mild detergent; this tactic helps bind the dust, preventing it from being stirred into the air. Avoid dry brushing or sweeping these particles. Instead, use microfibre cloths or electrostatic wipes designed specifically for fine particulate matter.

A HEPA-filter-equipped vacuum is essential to collect dust from corners, light fixtures, and tool housings. Seal collected dust in double-lined waste bags and dispose according to local regulations. To further reduce airborne dust exposure, work in stages and allow time between them to settle residual fine particles. Most importantly, always wear your FlowCore system throughout your cleanup procedure.

Effective Ways to Collect Fine Tile and Grout Dust

Tile cutting and grout sanding generate silica-rich dust—a recognised carcinogen. Efficient workshop cleanup in these scenarios demands a layered approach. Use wet cutting techniques whenever possible to limit dust formation. For dry tools such as oscillating multitools or grinders, ensure they are attached to extraction units compatible with HEPA-grade filtration.

Post-task, start with a fine mist over surfaces to trap loose dust. Next, deploy an anti-static brush attachment with your HEPA vacuum to clear sensitive areas like tool linings or bench surfaces. Clean floors using damp mops treated with dust-attractant solutions rather than generic cleaners. Floor mats can trap tile particulates, so clean or replace them regularly to prevent recirculation. Lastly, do a secondary vacuuming once particles have had time to settle. Never rely on compressed air—it only reintroduces harmful dust into the airspace.

Managing Timber Dust from Cutting and Sanding Projects

Timber dust, while often less chemically hazardous than other construction dusts, still presents severe health risks. Organic compounds released through sawing and sanding can cause allergic reactions, nasal blockages, and long-term pulmonary damage. Larger fragments settle quickly, but finer particulates—especially from softwoods—remain stubbornly airborne.

Implement dust collection at the source using power tools with integrated vacuum ports. Use downdraft tables to collect falling sawdust and prevent ground accumulation. Periodically clean these tables to prevent clogging. Workshop cleanup of timber dust should also focus on corners, rafters, and window sills where particles tend to gather unnoticed.

Apply wood-safe environmentally friendly surface cleansers during wipe-down processes to prevent warping or discolouration. Lastly, store softwood offcuts in sealable containers as they decay faster and produce mould-enhancing particles that exacerbate respiratory conditions if disturbed.

Ventilation, Vacuuming and Surface Wipe Techniques

Ventilation and air purification remain central to your workshop cleanup strategy. Begin by installing a crossflow ventilation system—utilising opposite facing vents for inflow and exhaust. Fit these vents with replaceable filters to prevent contaminants from re-entering the workspace. Portable air scrubbers can be used during active cutting sessions and during cleanup for additional control.

For vacuuming, opt for industrial models with high-efficiency filters certified for construction particulates, not just domestic groups. Use extendable nozzles to reach ceiling fixtures and intricate joinery. When wiping surfaces, select lint-free cloths treated for particle adhesion, and never reuse cloths between materials—cross-contamination may render your efforts futile.

Clean in sections, logically ordered to avoid double work. For example, start from high shelf levels and finish at floor zones. This top-down strategy ensures particle displacement is always progressing downward.

When and How to Replace FlowCore Filters

Knowing when to replace your FlowCore filters is crucial. The lifespan of an FFP2 or FFP3 filter depends on usage intensity and the specific material filtered. On average, for high-dust activities such as plastering or tiling, filters should be replaced after 8 to 16 hours of active use. Check the filter regularly for discolouration, clogging, or resistance to airflow—all indicators of saturation.

Replacement steps are straightforward. Power down the blower unit, remove the filter cartridge per manufacturer instructions, and dispose of it using sealed, non-permeable bags. Clean the housing area with a disinfectant wipe and install the new cartridge, ensuring it locks into place correctly. Record the replacement date and expected service life visibly on the housing for easy tracking.

Reusable vs Disposable Dust Masks for DIY

When it comes to workshop cleanup and airborne dust management, many DIYers question whether reusable respirators are worth the investment over cheaper disposable alternatives. In terms of safety, reusable devices like FlowCore offer superior protection due to their high-grade filter compatibility and full-face seal features. Disposable options, particularly those bought without medical or industrial certification, often fail to filter fine particulates completely and degrade quickly when exposed to moisture or oil.

From a financial and environmental perspective, reusable systems quickly validate their upfront cost. Unlike disposables that require constant repurchase and generate waste, reusable respirators can serve for years with good maintenance. Furthermore, they tend to incorporate passive airflow systems that reduce breathing resistance, crucial for extended projects.

For tasks involving plaster, grout, and timber—where dust is exceptionally invasive—the answer is clear: opt for reusable models such as FlowCore to ensure consistent safety and comfort.

Linking Dust Protection to Long-Term Health

Effective workshop cleanup directly influences long-term respiratory health. Chronic exposure to airborne particulates—including silica and wood dust—has been linked to asthma, COPD, and in some cases, even cancer. Governmental and occupational health bodies continue to publish updated guidance emphasising the role of proper PPE, ventilation, and safe disposal of dust waste.

Equipping oneself with tools like the FlowCore system is more than purchasing safety equipment—it’s an investment in future wellbeing. Consistent use of certified respirators may significantly reduce risks when compared to ad-hoc dust control measures. Moreover, adhering to recommended cleanup disciplines creates a positive feedback loop of cleaner air, healthier breathing, and increased productivity. For more detailed frameworks on health risks and detection timelines, consult these resources: Best cleaning methods for tile and grout and SEO tips tailored for UK businesses.

Conclusion: The Role of FlowCore in Safer DIY Cleanup

[CONCLUSION_CONTENT]

Great guide on workshop-cleanup-flowcore-plaster-tile-timber-dust – Community Feedback

Why is dust protection essential when working with plaster, tile, or timber?

Dust from plaster, tile, and timber contains fine particles that can harm your respiratory system. Using effective dust protection like FlowCore masks helps prevent breathing difficulties and long-term health issues in workshop environments.

How should I clean up tile and plaster dust in my workshop?

Begin by wearing a certified dust mask, then gently sweep or vacuum loose particles. Use damp cloths to capture remaining dust, taking care to prevent spreading it into the air. Clean tools thoroughly after use.

What kind of mask filter do I need for fine construction dust?

For fine dust from plaster, tile, or timber, choose a mask with FFP2 or FFP3-rated filters, such as the FlowCore system. These offer high filtration efficiency designed specifically for construction and DIY dust hazards.