Which Filter for Plaster Sanding? Why FlowCore & Torxup Lead

In This Article

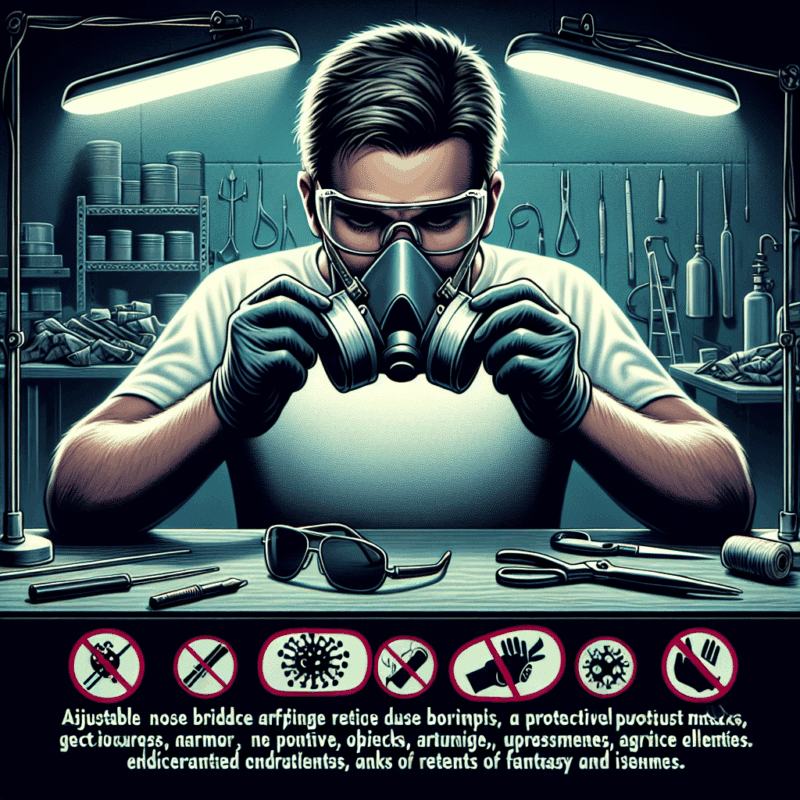

- Always choose FFP2 or higher when selecting a plaster sanding filter.

- Reusable masks like Torxup CoreMask enhance both safety and value.

- Replace filters regularly or when breathing resistance increases.

- Fit-test your mask setup before every use.

- Embrace superior hygiene practices to reduce airborne exposure.

Why Proper Filtration Matters for Plaster Sanding

Health Risks of Inhaling Plaster Dust

Using the correct plaster sanding filter is essential to maintain a healthy working environment during plaster-based renovations or construction. When sanding plaster, fine dust particles become airborne easily, presenting numerous health hazards. These ultrafine particles are often invisible to the naked eye yet can penetrate deep into the lungs. Prolonged exposure may result in respiratory ailments, irritation of the nasal passages, or, in severe cases, the development of chronic conditions such as occupational asthma or silicosis.

Construction workers and DIY enthusiasts alike are frequently exposed to these airborne contaminants. While short-term exposure may cause sneezing or coughing, ongoing inhalation of plaster dust leads to far more critical complications. Additionally, silica—often present in plaster materials—has been classified as a carcinogen. As such, both governmental regulations and health and safety authorities strongly advise the use of effective respiratory protection equipment. This is precisely where a robust, scientifically validated plaster sanding filter plays a critical role.

What is an FFP2 Filter and Why You Need It

Filter Grades Explained

Respiratory filters are defined by their filtration efficiency and resistance against inhaled particulates. European classification distinguishes filters primarily into FFP1, FFP2, and FFP3. Out of these categories, FFP2 filters are widely recognised for offering an ideal balance of breathability and protection. They trap at least 94% of airborne particles, making them suitable for exposure to moderate levels of hazardous dust—including plaster particulates.

To be clear, an FFP1 filter only captures around 80% of particulate matter, which is inadequate for most plaster sanding environments. On the other hand, FFP3 provides up to 99% filtration but can restrict airflow significantly and is often unnecessary for standard sanding tasks. Hence, the plaster sanding filter community overwhelmingly supports FFP2-rated filters for sustained use without excessive breathing resistance.

“FFP2 filters offer the optimum protection-to-comfort ratio, making them indispensable for safe plaster sanding operations.”

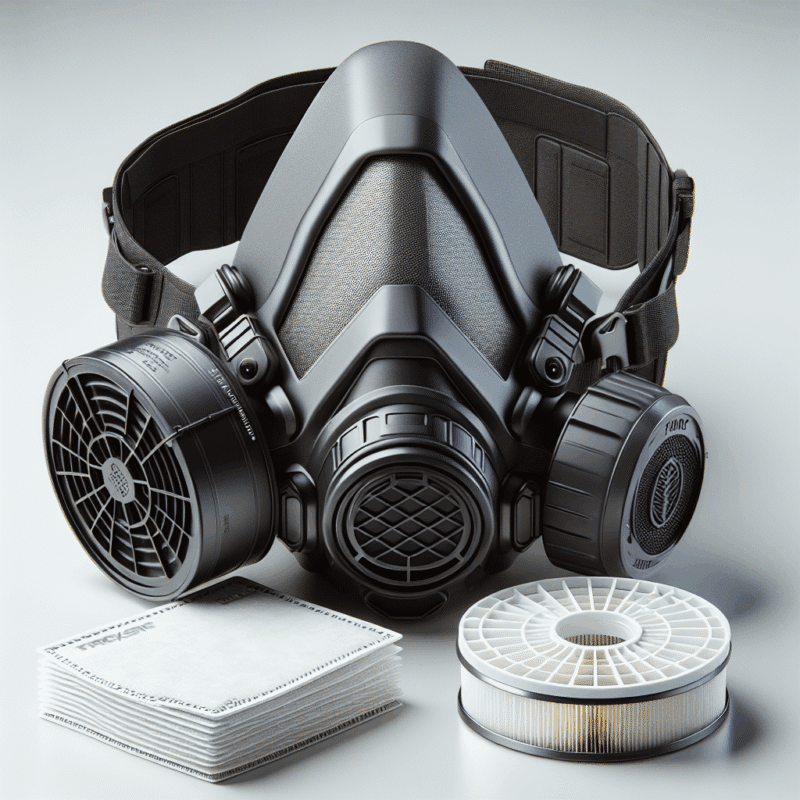

Standout Features of the FlowCore Particulate Filter

Dust Capture Technology in Action

The FlowCore particulate filter has become a benchmark in professional circles due to its precision-engineered dust-trapping layers. Unlike generic filters that offer limited permeability, FlowCore adopts a multi-layer filtration structure, reinforced with electrostatically charged fibres specifically designed to capture the smallest airborne particles. This is especially advantageous when dealing with plaster dust, notorious for its microscopic composition.

Another defining feature is its seamless integration with the Torxup CoreMask—a factor that helps maintain an airtight fit around the user’s nasal and oral region. By blocking inward leakage, the filter not only traps incoming debris but also ensures outward breath does not compromise the adhesive seal. These filters are independently tested to meet and exceed EN 149 standards, giving DIY professionals and renovators an added layer of confidence for healthier work sessions involving plaster sanding filter setups.

Why DIYers and Professionals Prefer the Torxup CoreMask

Build Quality and Comfort Review

The Torxup CoreMask has earned acclaim for its ergonomic design and reliable performance. Manufactured using latex-free silicone and reinforced with a dual-strap harness, this mask guarantees prolonged comfort and fit precision. When used in tandem with a FlowCore filter, the result is a balanced protective system capable of withstanding extended wear, often required in larger plaster sanding projects.

What sets the CoreMask apart is its custom moulding around the face’s unique contours. This mitigates air leaks and enhances suction grip—particularly vital for dusty environments. Professional contractors and hobbyists who regularly work indoors note a significant drop in dust ingress even under continuous usage. Importantly, the mask’s materials are also easy to sanitise, extending product lifecycle compared to disposable alternatives. Users consistently report positive experiences in online communities, highlighting improved breathing efficiency and reduced fatigue using this integrated plaster sanding filter system.

Reusable vs Disposable Dust Masks: What’s Safer?

Breaking Down Cost and Protection

When selecting the ideal solution for sanding tasks, many users face the dilemma of choosing between disposable masks and reusable masks with interchangeable filters. Although disposable masks might seem economically convenient, they fall short in both protection duration and effectiveness—especially during prolonged sanding work. In contrast, a sturdy mask like the Torxup CoreMask with a FlowCore plaster sanding filter provides unwavering filtration support and overall cost efficiency over time.

Reusable systems offer scalable benefits. The filters can be replaced without discarding the main unit, thereby reducing waste and long-term expenses. Furthermore, these systems meet stringent health and safety guidelines for construction environments. For professionals undertaking ongoing plastering or renovation projects, investing in a reliable reusable mask pays dividends—not just monetarily, but also in terms of lung health and peace of mind.

When and How to Replace Your Plaster Dust Filter

Signs You Need a Fresh Filter

Knowing when to replace your plaster sanding filter ensures that you maintain optimal protection. A common sign pointing to filter fatigue is increased breathing resistance. If you find yourself exerting more effort to inhale or exhale through the mask, it’s time for a change. Similarly, if you notice a plaster odour or dust leak around the seal, your existing filter may no longer be effective.

Another reliable indicator involves a visual inspection. If the filter appears clogged or discoloured, replacement becomes necessary. Most manufacturers, including FlowCore, recommend replacing filters after a defined number of usage hours—usually between 8 to 24 hours depending on intensity and environment. Always read accompanying usage guidelines, and never compromise on safety for convenience. After all, filtration efficacy is the front line of defence in any sanding operation.

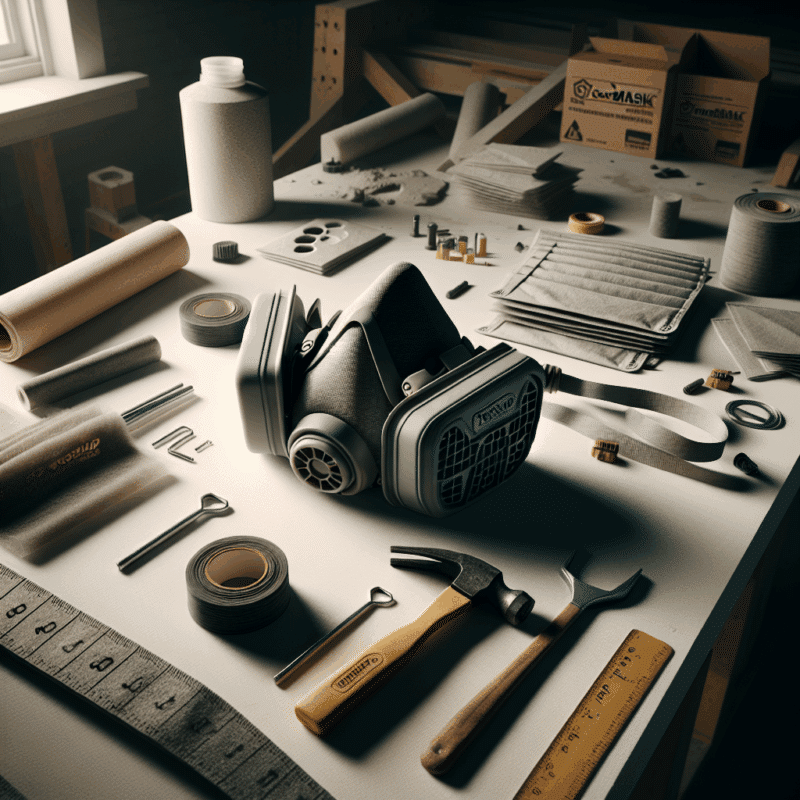

How to Use a FlowCore Filter with a Torxup Mask

Installation Tips for Best Results

Attaching a FlowCore plaster sanding filter to the Torxup CoreMask is straightforward but must be done correctly to ensure maximum seal strength and efficacy. Begin by inspecting the inner edge of the mask’s filter cavity to remove dust or residue from previous usage. Then, align the notch of the FlowCore filter with the inner slot of the CoreMask. Applying even pressure, press until it audibly clicks into place.

Before use, conduct a pressure fit test by covering the filters with your hands and inhaling. The mask should collapse slightly without any air escaping from the sides. If leakage occurs, readjust the mask’s tension strap or reseat the filter until the seal is flawless. This step is critical and should always precede mask usage. Following this disciplined approach ensures consistent particle capture and guarantees that your plaster sanding filter operates at peak efficiency.

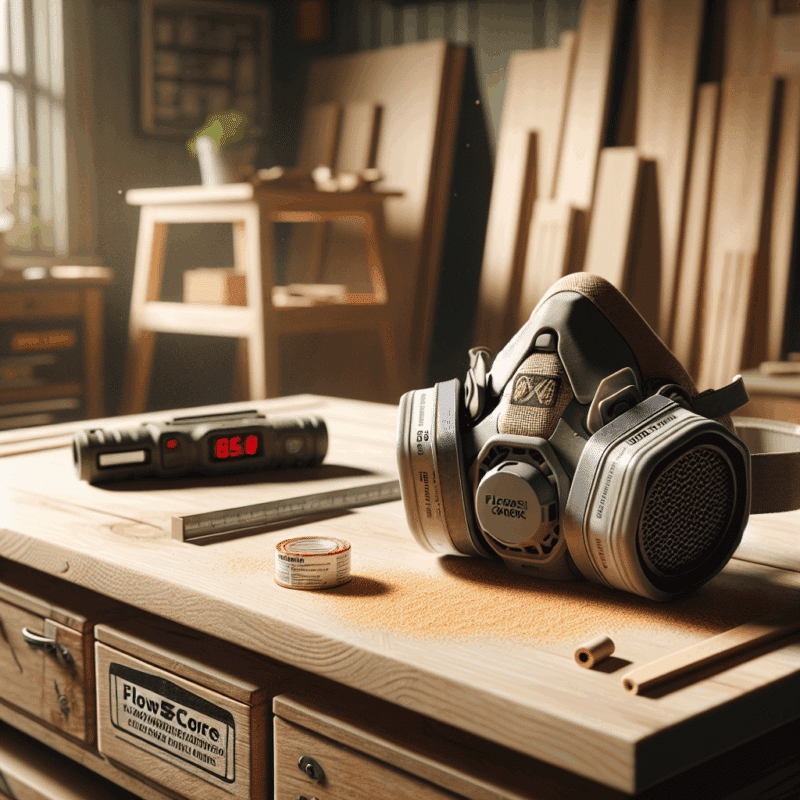

Plaster Sanding Dust Control Best Practices

Workshop Hygiene and Cleanup Tips

Beyond choosing the ideal plaster sanding filter, worksite cleanliness significantly contributes to dust management. One cornerstone strategy includes sealing off work areas using plastic sheeting to prevent particulate travel. Equally important is the use of extraction vacuums during sanding, ideally with HEPA filters, to capture airborne debris from the outset.

You should also perform regular clean-ups with damp cloths or mops instead of dry methods, as this reduces dust resuspension. Cleaning should be part of a scheduled regime—both before and after sanding operations. Tools and PPE, including your mask and filters, should be cleaned or replaced as directed. These sanitation practices significantly reduce health hazards and usability concerns, maintaining both project efficiency and air safety standards. See our guide to safe plaster sanding rules at Learn more about DIY dust safety and respiratory protection.

Community Insights and Respirator Feedback

What Fellow DIYers Say

Community feedback surrounding the Torxup CoreMask and FlowCore filter pairing remains overwhelmingly positive. In multiple forums and review threads, users commend the enhanced filtration, citing significantly cleaner breathing air compared to their previous disposable masks. One frequent DIY renovator stated, “I’ve been through four masks and nothing touches the performance of this combo. The difference in air quality is night and day.”

Others highlight the durability of the mask’s silicone structure as a major win for multi-day projects. The snug fit, absence of skin irritation, and simple upkeep are common themes in online testimonials. Additionally, recurring mentions suggest that second-time purchasers often upgrade to multi-packs of FlowCore filters after their first trial use. It’s clear why this system is now synonymous with serious plaster sanding tasks. Don’t miss more user testimonials located at Read a related article.

Where to Buy FlowCore Filters and Torxup CoreMask

Shopping Links and Recommendations

For those looking to purchase a reliable plaster sanding filter, several reputable suppliers now offer the FlowCore and Torxup CoreMask products both online and in retail outlets. It is crucial to verify product certification when purchasing filters—ensure they carry the EN 149 marking. Avoid counterfeit products by sourcing from authorised distributors.

You can explore high-quality selections at Construction respirator standards explained, or view bundled kits which include the CoreMask and multiple FlowCore filters at Eldris guide on multilingual content strategies. Always compare compatibility and review customer feedback before making a final decision to ensure you are securing a certified and comfortable fit for your specific sanding requirements.

Final Thoughts on Choosing the Right Plaster Sanding Filter

When it comes to protecting yourself during plaster sanding projects, no compromise should be made on air quality or comfort. The FlowCore filter and Torxup CoreMask duo represent an industry-standard solution that balances protection, cost-efficiency, and user experience. Understanding the importance of proper filtration—from choosing the right FFP grade to performing regular maintenance—can dramatically reduce health risks and increase the lifespan of your protective gear.

Incorporate community feedback, understand replacement intervals, and practise responsible cleaning habits to keep your workspace and lungs clear. Choosing the right plaster sanding filter isn’t merely about compliance—it’s a proactive step toward safer, more reliable project outcomes.

Great guide on which-filter-for-plaster-sanding-flowcore-torxup – Community Feedback

What type of filter should you use for plaster sanding?

For plaster sanding, use a certified particulate filter such as FlowCore that meets FFP2 or P2 standards to block fine dust and particulates.

How does the Torxup CoreMask support plaster dust protection?

The Torxup CoreMask, when paired with FlowCore filters, offers secure sealing and high filtration, specifically designed for fine plaster dust environments.

Do you need to change filters often when sanding plaster?

Yes, replace your filters regularly—especially after extended plaster sanding sessions—to maintain optimal protection and airflow.