When Ventilation Must Accompany ProDefend for Safe Solvent Use

In This Article

- Always use ventilation with solvents in enclosed spaces.

- Combine ProDefend masks with airflow strategies for optimal protection.

- Identify warning signs like odours, dizziness, and residue build-up.

- Use cross ventilation techniques wherever possible.

- Balance mechanical and natural airflow for consistent air quality.

- Understand and avoid common ventilation and PPE mistakes.

- Learn from real-world examples of workspace improvements.

- Ensure compliance with COSHH and related safety guidelines.

- Maintain ProDefend filters correctly for maximum longevity.

- Prioritise worker safety and comfort to improve outcomes and reputation.

Why Solvent Fumes Demand Ventilation

The risks of VOC accumulation indoors

Ventilation with solvents is a non-negotiable safety requirement in any enclosed workspace where volatile organic compounds (VOCs) are present. Solvent vapours, such as those from acetone, toluene, and xylene, are not only pungent but can also pose significant respiratory and neurological risks. Without adequate ventilation, these vapours rapidly accumulate in the air, creating hazardous exposure levels even during routine use.

Numerous studies indicate that VOCs can impair lung function, cause dizziness or headaches, and, with chronic exposure, lead to more severe conditions such as organ damage or cancer. The confined nature of indoor spaces traps these emissions, especially in work environments with poor airflow or multiple reuse of solvents in tasks like degreasing, thinning, or paint application.

Consistent ventilation with solvents prevents stagnation and buildup of airborne contaminants. It also significantly reduces the risk of long-term health issues for workers and occupants in commercial, industrial, and artisanal settings. This is not just about comfort; it’s about complying with occupational health regulations and maintaining a safe, breathable environment for all.

How ProDefend Filters Interact with Airflow

Understanding mask efficiency with proper ventilation

ProDefend filters are engineered specifically to intercept harmful VOCs and fine particulates under solvent exposure conditions. They’re highly effective when supported by active ventilation with solvents, maintaining optimal airflow through filtration channels. This balance ensures contaminants are both reduced in the air and diverted safely away from the respiratory zone of the user.

When users rely solely on respirators without concurrent ventilation, filters can become oversaturated faster. This diminishes both comfort and protection. Proper air movement provided by mechanical exhaust systems, air purifiers, or natural cross breezes preserves filter integrity. It also assists in keeping solvent vapours from overwhelming the breathing area surrounding the wearer.

Incorporating both ProDefend filters and robust airflow solutions multiplies safety. This dual-layer defence keeps occupancy zones within permissible exposure limits (PELs), protecting even during prolonged exposure activities such as spray-painting or adhesive application. Ensuring your workspace combines protective equipment and environmental control is essential for optimum safety.

“Combining ProDefend filters with controlled air movement reduces airborne solvent concentration by up to 65% more than masks alone.”

Signs Your Workspace Needs Better Ventilation

Recognising risk factors before exposure

Many users underestimate how quickly solvent fumes can accumulate in closed areas. Faint odours upon entering a space, frequent headaches among workers, or visible haze from evaporating chemicals are early signs of poor ventilation with solvents. If fans are inactive or exhaust points are lacking, exposure risks soar in hours, not days.

Other red flags include sticky residues on walls or equipment, discolouration near application points, complaints of dizziness by staff, and alarms from VOC sensors. Regularly reviewing HVAC air exchange rates and installing air quality monitors can offer objective insights into real-time air toxicity levels – ensuring you make informed decisions about ventilation strategies.

Responding proactively to these signs not only reduces potential health emergencies but also supports a compliant workspace aligned with current health and safety legislation. Learn more about DIY safety and respiratory protection for hazardous substances

Best Practices for Cross Ventilation

Simple ways to ventilate confined areas

Cross ventilation is one of the simplest and most effective approaches to managing solvent vapour build-up. This technique involves airflow entering from one area and exiting from another, usually via windows or vented doors placed opposite each other. This setup allows fresh air to push contaminated air out, quickly diluting internal pollutants.

To elevate its effect, combine passive structures (windows, louvers) with active elements like extractor fans. While open doors help air movement, natural cross images may not suffice without directional airflow. Placing a box fan in a sealed window pane can pull air outwards while a fan at the opposite end draws fresh air inwards.

If architecturally limited, ducting-based portable exhaust systems can provide similar effects. Always ensure that your cross-flow doesn’t recirculate solvent-rich air into adjacent rooms. Instead, direct it outside or into dedicated fume hoods equipped with ProDefend-compatible filtration. Official safety standards for solvent ventilation

Mechanical vs Natural Ventilation Options

Choosing the best airflow solution for your project

Selecting between mechanical or natural ventilation depends on workspace constraints, solvent types, and exposure frequency. Mechanical ventilation systems include roof-mounted extractors, inline ducted fans, HVAC systems with carbon filtration, and portable fume extractors. These systems are particularly useful in sealed or high-risk spaces where natural airflow is insufficient.

Natural ventilation, by contrast, relies on architectural layout to encourage air exchange — it requires careful placement of operable panels and unobstructed inlets and outlets. While it’s cost-effective and passive, it may not consistently remove high concentrations of solvents, especially during colder months when windows remain shut.

For most industrial and commercial users, a hybridised approach delivers the best value. Natural elements reduce costs, while mechanical solutions moderate exposure under higher-volume conditions. Keep in mind that ProDefend masks should always complement these systems rather than replace them.

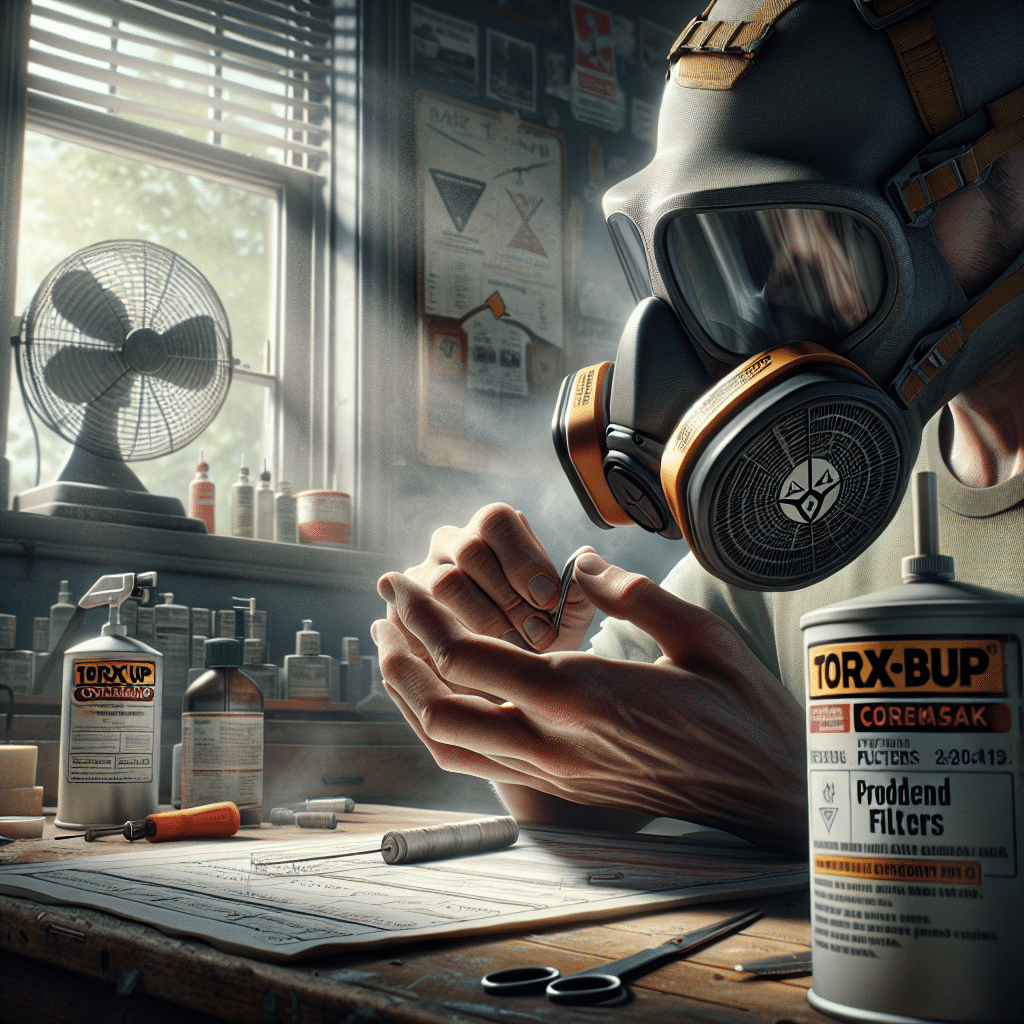

Using Masks and Fans Together Effectively

Creating synergy between respirators and air movement

Many assume that wearing a high-grade solvent mask is sufficient. However, even premium units like the ProDefend series achieve their maximum protective efficiency only when used in conjunction with effective airflow. This combination ensures vapours are dispersed before reaching dangerous levels, reducing filter fatigue and skin exposure.

Position extractor fans to redirect solvent fumes away from the user’s breathing space. If working over open solvent containers, use table-level fans pointed outward, not inward, to prevent fume recirculation. Masks protect the lungs, while fans cleanse the surrounding environment. Together, they create a layered defence strategy.

Also, bear in mind that dual-system use extends the life of ProDefend filters, allowing fewer mask changes and cleaner working conditions. It’s not just about efficiency; it’s about cost, employee wellbeing, and regulation adherence. Read a related article

Mistakes to Avoid With Indoor Solvent Use

Common errors that increase exposure risk

One of the most frequent mistakes is underestimating the importance of continuous air exchange while using solvents. Sealing windows for “temperature control”, reusing old filters, or neglecting to assess the room’s airflow pattern can expose users to avoidable toxicity.

Misuse of personal protective equipment (PPE) is also common. Wearing masks incorrectly, choosing filters not rated for VOCs, or removing gear prematurely disrupts safety integrity. Additionally, placing air movement sources too close to solvent containers can stir vapours toward users, rather than expelling them elsewhere.

Proper ventilation with solvents also means never relying on odour alone to indicate safety. Some solvents have sweet or mild smells that mask their true danger. Always default to usage guidelines and solvent safety data sheets (SDS) as your framework for implementation. Understanding cross-border product compliance

Real Stories: Why Users Added Ventilation

Community insights on projects that improved safety

Across the UK, hundreds of facilities have revised their solvent handling protocols after recognising risks. One workshop in Manchester reported a 40% drop in employee headaches after implementing extractor fans alongside ProDefend respirators. “We didn’t realise how little airflow we had until we used smoke pencils during a site audit,” said their health officer.

Another case in Bristol highlights a garage that began using solvent-based spray paints indoors. After initial complaints of disorientation from staff, the owner installed an exhaust hood and window louvers. Within days, conditions normalised, and productivity increased. Ventilation with solvents was the trigger that helped them meet legal compliance effortlessly.

These examples show that improvements need not be costly — awareness and small equipment changes can yield noticeable health and safety benefits.

Compliance with Safety Standards

How to ensure your workspace meets regulations

In the UK, the Control of Substances Hazardous to Health Regulations (COSHH) govern how volatile substances should be handled. Employers are legally required to establish adequate control measures — ventilation with solvents falls under that directive. Adequate local exhaust ventilation (LEV), air quality monitoring, and PPE usage are expected components of any solvent-use policy.

Failure to adhere to these guidelines could trigger inspections, fines, or even operational shutdowns. Maintaining air samples within acceptable limits, documenting airflow performance, and calibrating ventilation equipment routinely is key. Use signage, employee training modules, and continuous improvement tools to ensure full compliance across your team.

Pairing compliance with practical protective measures like ProDefend filters ensures both ethical responsibility and regulatory comfort. Don’t view it as a cost — view it as risk prevention.

ProDefend Mask Maintenance in Solvent Conditions

Tips for longer-lasting filtration performance

To ensure your ProDefend mask maintains peak filtration in environments heavy with solvents, proper care is indispensable. After each use, clean mask surfaces with a solvent-resistant wipe and verify that the seal remains intact. Store the mask in a dry, well-ventilated container away from chemical exposure, which can degrade filter media prematurely.

Replace filters according to the manufacturer’s recommended schedule or sooner if breathing resistance increases. Never attempt to “stretch” usage — doing so compromises safety. Periodic fit testing ensures that the mask continues forming a reliable seal. Users should also inspect for cracks or brittleness, especially if the equipment is used in varied temperature environments.

Training team members on maintenance procedures should become a part of your safety protocol checklist. Doing so extends equipment longevity, optimises performance, and keeps protection consistent under all solvent-handling circumstances.

Conclusion: Setting a Safe Standard

It’s clear that ventilation with solvents must be more than a suggestion — it is a professional imperative. Whether you’re working in an industrial plant, an art studio, or a commercial repair bay, the combination of ProDefend filtration systems and effective airflow can protect health, extend equipment lifespan, and uphold legal compliance.

From recognising early signs of contamination to hybridising mechanical and natural ventilation, the right knowledge and equipment can transform hazardous environments into safe, efficient spaces. Addressing exposure proactively ensures your team’s safety, your site’s reputation, and your long-term sustainability in any solvent-intensive operation.

Great guide on ventilation-support-with-prodefend-filters-solvents – Community Feedback

When must ventilation be used with ProDefend filters for solvents?

Ventilation must be used with ProDefend filters whenever you’re working indoors with solvents, particularly those emitting VOCs, to ensure harmful vapours are reduced below safe exposure limits and to assist the mask’s filtration. Always ventilate in confined or poorly ventilated areas.

Are ProDefend respirators alone enough protection against solvent fumes?

No, using ProDefend respirators alone is not enough. Proper ventilation is essential alongside masks to dilute and remove vapours, preventing the build-up of hazardous or explosive concentrations in your workspace.

What are effective ways to ventilate when using solvents?

Effective ventilation includes using extraction fans, opening windows and doors for cross-ventilation, or employing mechanical exhaust systems to remove and dilute solvent vapours at the source, ensuring cleaner, safer air.