When Ventilation Is Needed With ProDefend: Safe Solvent Use Guide

In This Article

- Ventilation for solvents is essential to protect against VOC exposure

- ProDefend masks require proper ventilation support to be effective

- Passive airflow is insufficient for high-toxicity tasks

- Regulations demand both PPE and extraction systems

- Poor ventilation leads to serious health risks

Why You Need Ventilation With Solvents

Understanding solvent vapours and air quality risks

Ventilation for solvents is non-negotiable wherever chemical solvents are in use. These substances emit volatile organic compounds (VOCs) which vaporise at room temperature and disperse into the surrounding air. In enclosed environments, these fumes accumulate quickly, degrading air quality and inducing a range of health risks. Short-term exposure to solvent vapours can lead to dizziness, headaches, nausea, and respiratory irritation. Long-term inhalation may result in neurological damage, liver and kidney impairment, or carcinogenic effects depending on the class of solvent used.

Inhalation isn’t the only danger. VOCs are also highly flammable, creating explosive atmospheres if ventilation is inadequate. When solvent-based work is conducted without a tailored airflow system, workers operate within invisible hazards even when wearing carbon-filter respirators. The presence of odourless solvents like xylene and chloroform adds to the danger, making it imperative that airflow is engineered rather than assumed.

Relying solely on personal protective equipment (PPE) without addressing room-scale exposure compromises both safety and compliance. Even advanced masks like ProDefend struggle to provide total protection in poorly ventilated environments.

What ProDefend Can (and Can’t) Do

Limits of carbon filters in workshop environments

ProDefend is a high-performance respirator system equipped with carbon filtration designed to mitigate exposure to solvent fumes. It filters many airborne hazards commonly found in professional workspaces. However, even cutting-edge PPE like ProDefend is not a silver bullet. It must be part of a broader safety strategy that includes active ventilation for solvents. Filters have a saturation point. Once overwhelmed, they no longer provide protection unless replaced. Moreover, ProDefend may efficiently protect the respiratory system but does nothing to shield the skin, eyes, or ambient environment from hazardous vapours.

Another important caveat concerns the nature of the workplace. In confined or enclosed areas, the rate at which solvent vapours disperse surpasses the filtration speed of any respirator. This creates a constant build-up of invisible pollutants unless extracted mechanically. Even short-term exposure under such conditions can exceed occupational exposure limits set by regulatory bodies.

“Even the best filtration mask is only as protective as the air you breathe through it.” — Health & Safety Laboratory, UK

Recognising Symptoms of Poor Ventilation

What happens when fumes accumulate indoors

One of the first signs that ventilation for solvents is inadequate is physical discomfort among workers. You’ll notice increased complaints of irritation—particularly in the eyes, nose, and throat. Concentration issues and fatigue may follow due to reduced oxygen levels or the narcotic effect of VOCs. In extreme cases, fainting or cognitive confusion can occur. These are not mere inconveniences: they are clinical indicators that your workspace is unsafe.

Long-term indicators of chronic exposure include liver enzyme abnormalities, hormonal imbalances, and neurological symptoms such as tremors or memory loss. Importantly, relying solely on olfactory cues is misguided. Some solvents are entirely odourless at concentrations that already breach legal thresholds. The only reliable method of diagnosis is environmental monitoring and using both PPE and active ventilation systems.

Setting Up Effective Ventilation In Your Workspace

Mechanical vs passive airflow—what works best?

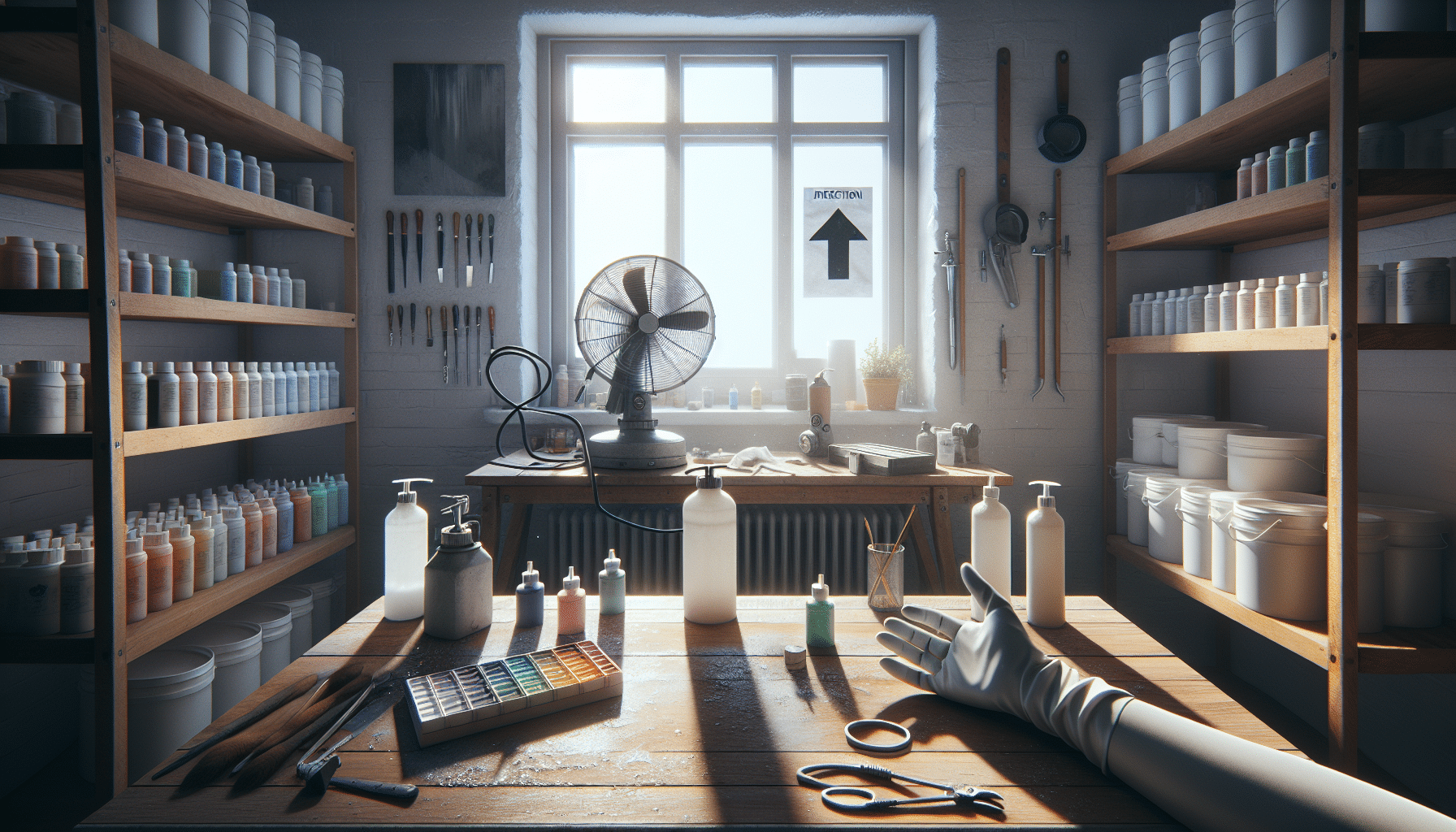

Not all ventilation is created equal. Passive systems, which rely on natural airflow through open windows or doors, may suffice for minimal solvent use. However, they are insufficient for professional or industrial settings. Mechanical ventilation for solvents ensures a controlled and consistent exchange of air. This typically involves local exhaust ventilation (LEV), which captures vapours directly at the source, discharging them safely outside the structure.

Directional airflow is essential. Air should sweep across the work zone and towards extraction points. Ceiling fans or open doorways aren’t reliable enough without strategic orientation. Moreover, advanced systems often include air filtration units like HEPA or activated carbon filters on the exhaust path to meet environmental discharge rules. Choosing the correct fan capacity and ensuring regular maintenance are critical to system effectiveness.

Choosing the Right Mask-Filter-Ventilation Combo

Pairing PPE correctly for solvent protection

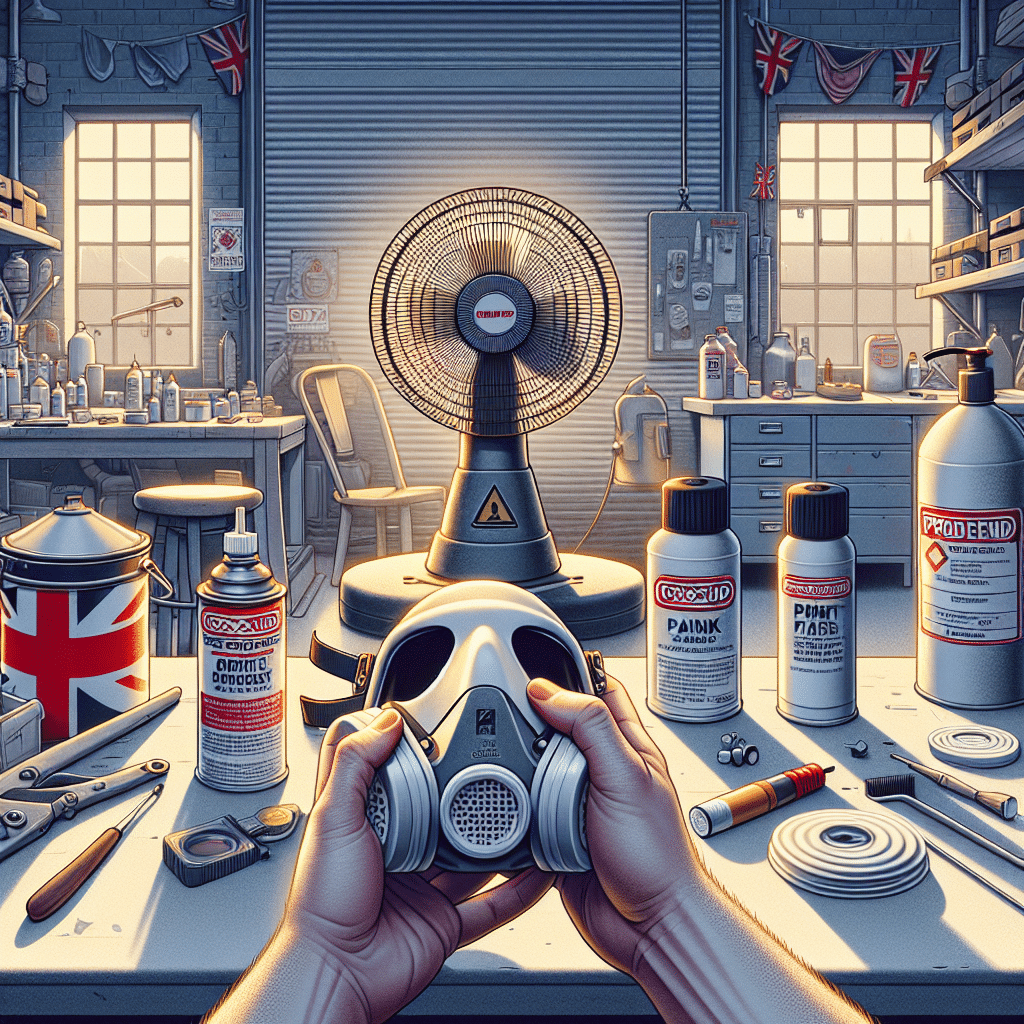

PPE like ProDefend plays a vital role, but only when used as part of a comprehensive protection strategy. The first step is identifying the solvents in use. Organic vapours like benzene, toluene, and trichloroethylene each demand specific cartridges or filter classifications. A mismatch can render your equipment ineffective. Equally vital is evaluating exposure duration and volatility levels.

Proper usage demands vigilance. Cartridges should be replaced as per manufacturer’s guidelines or sooner based on air monitoring data. A standard approach is combining half-face or full-face respirators with forced-air ventilation or downdraft tables. For high-exposure tasks, add disposable coveralls, goggles, and chemically resistant gloves. Always remember: PPE is your last line of defence. If your room’s solvent levels are unregulated, even perfect pairing can’t compensate for toxic air.

When Professional Advice Is Essential

High-toxicity jobs and unknown solvents

Ventilation for solvents becomes a professional responsibility when dealing with high-toxicity tasks such as industrial painting, lacquer thinning, degreasing, or solvent-welding plastics. These applications often involve chemical interactions that intensify hazards. In cases where the precise composition of a solvent is unknown—or when using proprietary blends—consulting a certified occupational hygienist is essential.

These experts assess the level of exposure using tools like personal air monitors and establish Total Exposure Limits (TELs) based on international guidelines. They can also recommend or design customised ventilation plans including ducting, extraction fans, and fail-safe alarms. Without professional input, companies risk breaching legal regulations and endangering employees’ health.

Legal and Safety Standards You Should Know

Regulatory guidance from OSHA and others

Across the UK, EU, and international jurisdictions, there are clear legal obligations regarding ventilation for solvents and exposure limits. In the UK, guidelines are issued under COSHH (Control of Substances Hazardous to Health). Employers must conduct routine risk assessments and ensure airborne solvent concentrations remain below workplace exposure limits set by the Health and Safety Executive (HSE).

Globally, institutions like OSHA (Occupational Safety and Health Administration) and the European Chemicals Agency (ECHA) enforce regulations that may also apply, especially if your business imports or exports products. Failure to comply exposes organisations to litigation, fines, and reputational damage. Ensure that all PPE and ventilation systems meet British Standards (such as BS EN 529 for respiratory equipment) and that certifications are up-to-date. Reference `Learn more about Respiratory Protection & Air Quality in DIY` for a full checklist compliant with UK mandates.

Real Feedback: User Experiences With ProDefend

Ventilation setups and filter limits in practice

Workshop professionals using ProDefend often highlight its ergonomic design and effective filtration. However, recurring testimonials underscore one vital point: the mask excels only when used with active ventilation. In one automotive body shop, a technician reported headaches and irritation despite wearing a fully sealed mask. The root cause was inadequate airflow in their paint booth.

Another case study from an industrial print company revealed that combining activated carbon room filters with ProDefend reduced VOC levels by 70%. Yet, it was only after installing an exhaust fan system with direct source capture that their compliance levels dropped within safety limits. These insights underline that personal experiences echo regulated guidance—ventilation for solvents must accompany even the most robust masks. More real-world accounts can be found at `Read a related article`.

FAQs About Solvent Fumes and Workshop Safety

Common questions answered clearly

Q1: Can I work with solvents using only a respirator?

A: No. A respirator is not a standalone safety measure. Proper ventilation for solvents is crucial for dispersing fumes and maintaining safe air quality.

Q2: How often should I replace my ProDefend filter?

A: It depends on usage frequency, solvent type, and air quality. Generally, filters should be replaced every 20–40 hours of use or when breathing resistance increases.

Q3: What is the sign of a saturated carbon filter?

A: Increased odour detection and breathing difficulty. Once saturated, the filter can no longer protect you effectively.

Q4: Are there legal penalties for poor ventilation systems?

A: Yes. Under COSHH and other national guidelines, insufficient ventilation can result in fines, legal action, or shutdown mandates. Refer to `Official ventilation requirements for working with solvents` for updated compliance law.

Your Pre-Job Safety Checklist

Before grabbing the paint or solvents

Before every job involving solvents, execute a strict protocol:

- ✔ Identify all solvents and their hazard data sheets

- ✔ Ensure your workspace has mechanical ventilation or LEV

- ✔ Test ProDefend masks and inspect for integrity

- ✔ Confirm the pairing of filters with solvent types

- ✔ Replace spent filters or cartridges as scheduled

- ✔ Monitor workspace VOC levels using detection badges or electronic monitors

- ✔ Keep a first aid kit and emergency wash station nearby

- ✔ Document all safety checks and training sessions

External certifications and signage (such as COSHH inspections) should be visibly posted within the work area. For a printable version of this list, visit `Boost UK site traffic with automated SEO strategies`.

Conclusion: Always Combine Filters and Ventilation

While ProDefend offers exceptional personal protection, it is not designed to function alone. Ventilation for solvents provides the environmental safeguard necessary to turn toxic atmospheres into safely managed work zones. Ignoring it places users at risk, compromises compliance, and undermines the effectiveness of even top-tier filtration systems. Always design your safety setup with multi-layered defence: source identification, ventilation systems, PPE pairing, and regulatory adherence. Doing so protects your health and ensures long-term professional viability.

Great guide on when-ventilation-must-accompany-prodefend-for-solvents – Community Feedback

When must I use ventilation alongside ProDefend when using solvents?

Ventilation is required when working with solvents due to the risk of vapour build-up, which carbon filters may not fully block. Use local exhaust or increase airflow whenever handling any volatile or high-toxicity chemicals.

Do carbon filters protect me from all solvent fumes?

Carbon filters have limits—they reduce many vapours, but some highly volatile, high-concentration, or chemically reactive solvents can penetrate filters. Always ventilate well, even with certified filters.

What is the safest way to work with paint and solvent vapours indoors?

Wear a fitted respirator with appropriate filters like ProDefend, and ensure continuous ventilation with fans or open windows to prevent fume build-up and maintain clear air in your workspace.