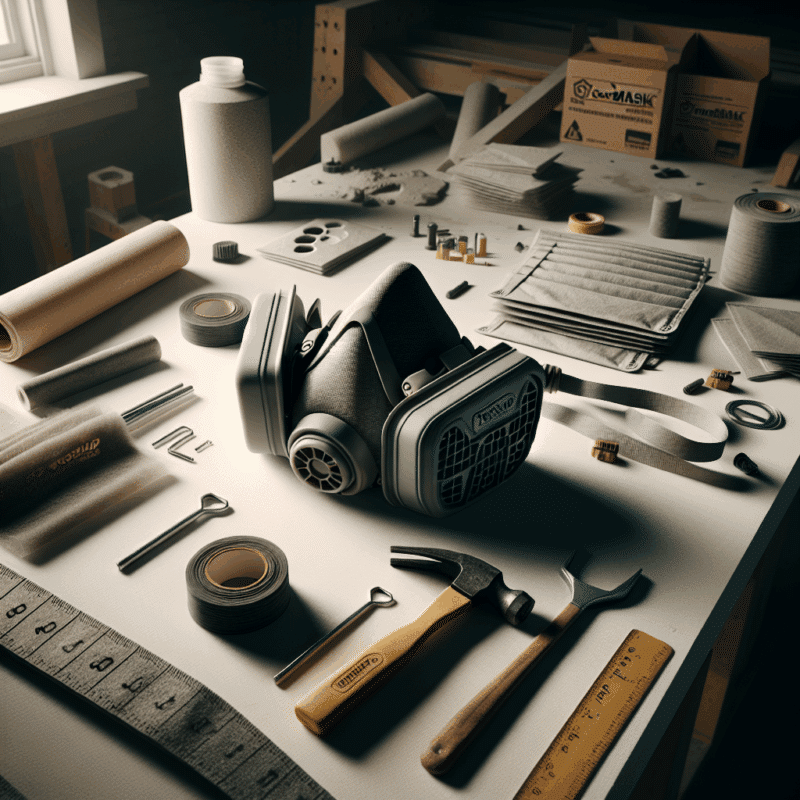

Stop Mask Leaks Fast: CoreMask Quick-Fit Torxup Tips Guide

In This Article

- Use CoreMask’s Quick-Fit Torxup system for fast and reliable sealing.

- Identify and monitor leak-prone areas: nose, chin, and sides.

- Clean masks regularly to preserve sealing integrity and comfort.

- Keep straps in optimal condition; replace when stretched or frayed.

- Follow a consistent fitting routine each day.

- Leverage user communities for expert tips and troubleshooting ideas.

Understanding Why Dust Masks Leak

Common Causes of Poor Mask Seals

To effectively achieve mask leak prevention, one must first understand why dust masks tend to leak in the first place. Fit and seal integrity are critical, especially in job sites where airborne particles pose a significant health risk. Leaks commonly occur when the mask fails to contour to the face properly, leading to gaps at various pressure points like the nose bridge, chin, or sides of the cheeks. Even high-quality filtration is rendered ineffective without a tight seal.

Improper strap tension is another frequent culprit. Over-tightening can distort the mask’s shape, while under-tightening allows shifting during movement. Facial hair can also compromise the seal by preventing consistent contact along the mask edges. Additionally, dirt-encrusted or worn-out seals further reduce performance over time.

Environmental and user behaviours contribute too. Quick turning of the head, frequent talking, sweating, or sudden facial movements can break an otherwise stable seal. Inadequate cleaning routines lead to clogged filters and compromised material elasticity, which further degrades the fit. Addressing these issues is the first essential step in successful mask leak prevention.

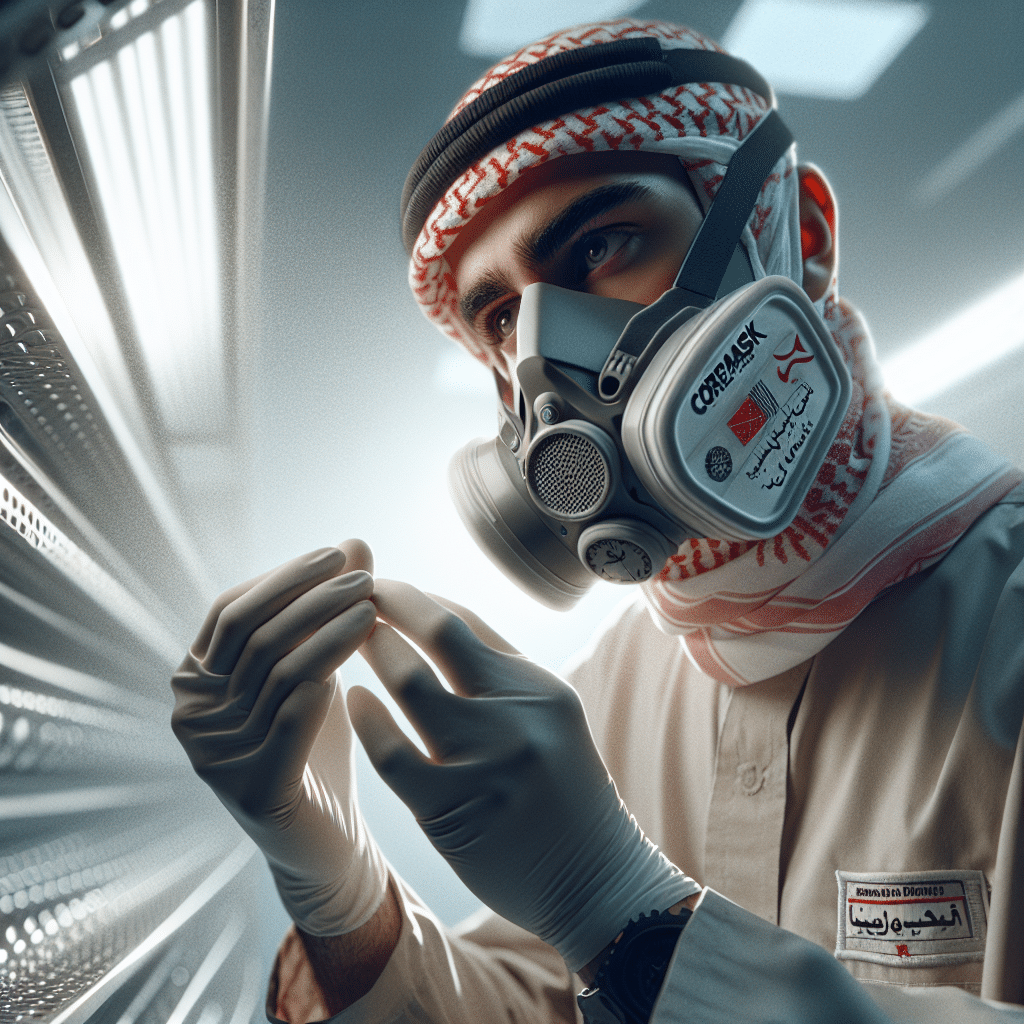

How the CoreMask Solves Leak Issues

Benefits of the Quick-Fit Torxup Design

The CoreMask system with its Quick-Fit Torxup design offers an innovative approach to mask leak prevention by ensuring a secure fit in seconds. The design integrates torque-calibrated strap adjusters that apply uniform pressure across the mask’s sealing surface. Unlike traditional fastenings that often pull unevenly on the mask body, Torxup distributes tension evenly, reducing distortion and sealing gaps automatically.

This smart design is particularly useful for professionals who need to don and doff masks several times during a workday. Not only does Quick-Fit Torxup allow for faster fitting, but it also maintains a consistent level of pressure, encoded via visual torque indicators. Workers can know when their mask is perfectly fitted without feeling for minor leaks manually.

Moreover, CoreMask’s focus on ergonomics means each mask accommodates varied facial structures while using memory-seal elastomers that adapt to movement. The result? A seal that remains intact even as the wearer climbs ladders, bends, or rotates the head quickly. This combination of adjustability, material quality, and intelligent feedback makes the CoreMask stand out from generic solutions when it comes to mask leak prevention.

“Since switching to CoreMask with the Quick-Fit Torxup system, our crew hasn’t had a single complaint about mask leaks. Game-changer.” – Site Safety Manager, London

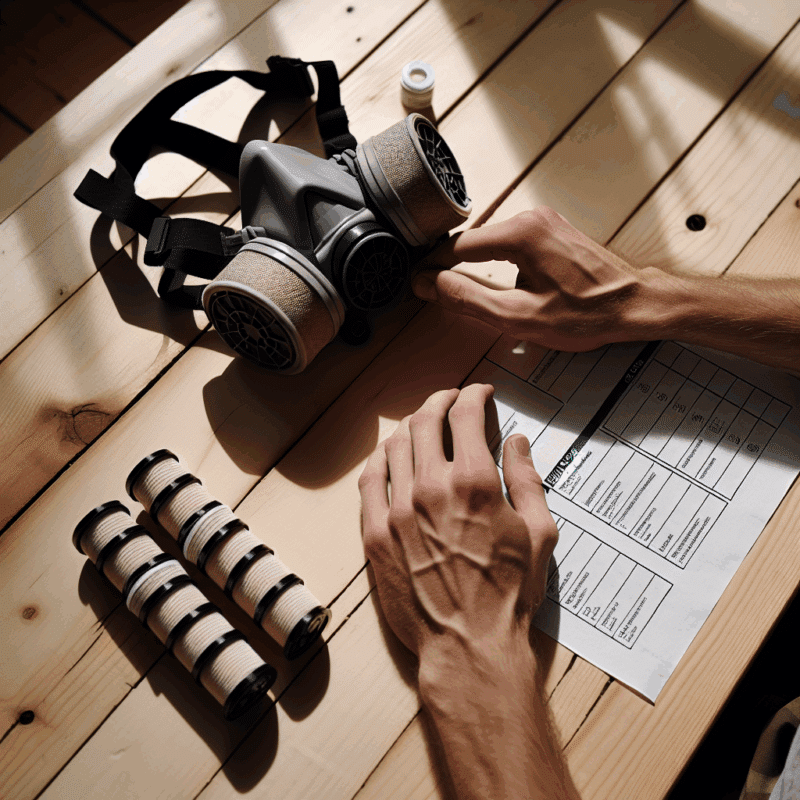

Quick-Fit Tips for a Better Seal

Step-by-Step Strap Adjustment Guide

Perfecting mask leak prevention requires not only the right equipment but also a correct donning technique. Here’s a proven step-by-step Quick-Fit protocol that ensures optimal seal integrity using CoreMask’s Torxup mechanism:

Step 1 – Pre-Check: Before wearing, inspect the CoreMask for any visible wear, deflated seal ridges, or damaged straps. Clean the mask if necessary. Ensure your face is dry and free of oils or lotions.

Step 2 – Position the Mask: Place the nose bridge at the top and align the mask symmetrically with your facial features. The lower section should comfortably follow the contour of your jawline.

Step 3 – Engage Quick-Fit Torxup: Pull the head straps and engage the Torxup dials. Gradually torque the straps until the indicator window turns green—this signals the optimal tension for the seal without risk of over-tightening.

Step 4 – Test the Seal: Conduct a user-seal check by exhaling sharply and feeling for air leaks with your hands. If a leak is detected, lightly adjust the strap or realign the mask. Repeat until the seal is uniform.

These steps not only promote dependable mask leak prevention but also reduce daily fitting inconsistencies often experienced by workers using less advanced systems. Maintaining the ritual enhances performance and comfort over long shifts.

Areas That Commonly Leak

Chin, Nose, and Side Seal Checks

Understanding leak-prone regions of the face allows for targeted mask leak prevention techniques. Firstly, the nasal bridge is the most frequent offender due to its complex contour and the presence of glasses or goggles. To address this, CoreMask integrates a multi-flange nose ridge that flexes vertically and laterally, improving conformity across this curve.

The chin strap area is another common breach site. If the mask sits too high or low on the chin, movement during jaw activity—like speaking or drinking—can cause the mask to ride up and break contact. CoreMask’s extended under-chin harness distributes vertical tension, anchoring the mask in place regardless of movement.

Side leaks around the cheeks often arise from misaligned tension on the lateral seals. The Torxup guides allow fine tuning of this region, counteracting any asymmetrical pull. Soft padding in the mask body adds compliance, helping the mask settle naturally against both left and right facial curves.

Regularly check each of these zones when fitting your mask to ensure complete coverage. Incorporating these checks into your PPE routine reinforces effective mask leak prevention every time.

Routine Maintenance to Prevent Leaks

Cleaning and Strap Integrity

Maintenance is a cornerstone of ongoing mask leak prevention. Even the best-designed masks lose their efficacy without proper care. CoreMask units are constructed with cleanable composite polymers and replaceable elastomer seals, which makes them suitable for daily upkeep.

Begin each shift with a wipe-down of sealing surfaces using alcohol-free disinfectant. Oils from your skin or airborne contaminants can degrade elasticity. Weekly deep cleaning—soaking in lukewarm water with non-aggressive soap—removes microparticles embedded in soft surfaces.

Strap integrity determines tension reliability. Examine strap fibres for signs of fraying, expanding, or stiffness. If the Torxup dial no longer meets its visual indicator within normal turns, the stretch memory may be compromised, and the strap should be replaced. Learn more about Respirator and Dust Mask Usage & Maintenance

Don’t overlook the internal foam supports—they must rebound to original form after compression. Deforming materials signal fatigue and can contribute directly to poor seal retention. Scheduled part inspections and replacements uphold the reliability of the CoreMask system, making consistent mask leak prevention an achievable standard.

What to Do If Your Mask Still Leaks

Troubleshooting Persistent Seal Failures

If leaks persist despite proper fitment, proactive troubleshooting is necessary. Start with a thorough visual inspection of key contact points. Place the mask on a clean surface and check for seal warping or hardened edges. Less flexible areas often indicate that the mask has overheated in storage or dried out due to poor conditioning.

Next, assess strap alignment. Misrouted straps can unevenly compress the mask, opening gaps where they shouldn’t exist. Also, intermittently check for hair obstruction under the seal line. Stubble growth over a day can unexpectedly reduce sealing effectiveness.

If the mask feels too rigid or uncomfortable, users may forgo correct positioning unconsciously. It may be time to switch to a different CoreMask size. Multiple fit profiles are offered, and using the incorrect variant may lead to chronic leaks over months of use.

Lastly, if your operating environment involves high temperature or humidity, moisture vapour permeability must be regularly evaluated. Some users may benefit from CoreMask humid vent inserts or anti-condensation guards. These additions improve comfort and prevent leaks caused by sweat accumulation.

If in doubt, visit the full Read a related article for diagnostic videos and fit guides tailored to CoreMask models.

Comparing With CPAP Mask Leaks

Overlap in Fit Challenges and Solutions

Interestingly, the principles of mask leak prevention relevant to occupational settings overlap heavily with those observed in CPAP therapy across medical domains. CPAP users similarly struggle with seal breaches at nasal ridges, chin interfaces, and cheek contours. Moisture, improper adjustment, and seal collapse remain dominating issues both in trades and in health applications.

While the design intention of a CPAP mask and a dust safety mask differs, both rely on high-surface contact tension across dynamic facial zones. Lessons from CPAP mask fitting—such as using dual tension zones, fit testing with airflow, and periodic seal conditioning—translate well to improving occupational mask design.

CoreMask integrates these learnings by offering ergonomic curvature mapping and fit kits that help users find their perfect match. If you’ve encountered CPAP leaks, you’ll find the approach used by CoreMask more intuitive and scientifically sound. For more on this parallel, refer to Expert insights into why masks can leak.

Community Tips From Tradespeople

Most Liked Ways to Prevent Mask Leaks

Experience from the field often bridges gaps that engineering cannot fill. We gathered top tips from tradespeople who rely on mask leak prevention daily:

- “Shave before your shift unless you’re using a specialised beard-compatible seal.”

- “Store masks hung up, not crushed in bags—they’ll hold their shape better.”

- “Torque your strap at the back first, then settle the mask on your nose last.”

- “Use a breath mist spray during winter months to reduce condensation weakness.”

- “Replace the mask before it dies—don’t wait until it stops sealing.”

These firsthand insights underscore the value of community in engineering better performance. Such industry-specific feedback loops are vital to ongoing innovation in mask leak prevention. For more ideas, join the CoreMask community forum via Upcoming safety rules for compliant products.

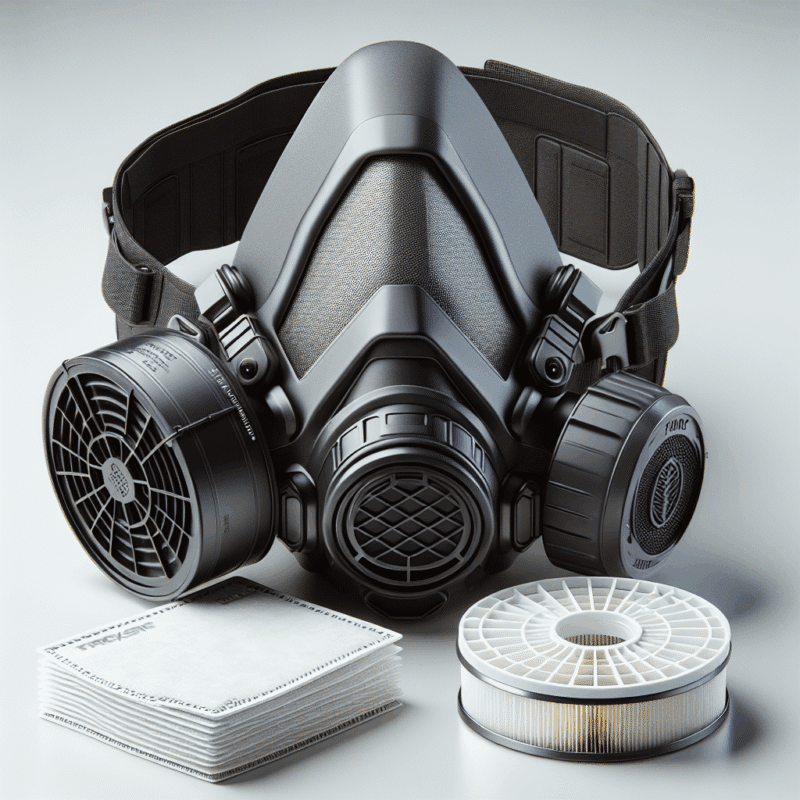

Why You Should Trust Torxup Products

Quality, Safety, and Performance Guarantee

Torxup’s commitment to safety and performance is backed by rigorous product testing and ISO-conformant quality assurance protocols. Each CoreMask undergoes real-world stress testing and fit simulations before leaving the factory floor. These masks don’t just comply with dust protection regulations— they exceed EN149 and FFP3 sealing standard thresholds.

Material selection undergoes chemical resistance vetting, ensuring that users in environments rich with paint fumes, solvents, or abrasives won’t see degrading effects over time. Additionally, Torxup’s patented torque feedback system is a proprietary innovation built solely to address mask leak prevention in practical, scalable formats.

The brand stands behind its products with a 12-month fit guarantee and access to a responsive customer service team that understands the demands of industrial use. Torxup isn’t simply selling a mask; it’s delivering a system designed from the ground up to outlast and outperform disposable alternatives.

Takeaways for Better Mask Fit

Mastering mask leak prevention is vital for any worker exposed to dusty or hazardous job environments. From proper fitment strategies to innovative designs like CoreMask’s Quick-Fit Torxup system, success lies in consistent application and proactive maintenance. This guide details not only how to avoid leaks but also why prevention matters and whom to trust with this crucial responsibility.

Great guide on stop-mask-leaks-coremask-quick-fit-torxup-guide – Community Feedback

Why does my CoreMask leak around the edges?

A CoreMask may leak around the edges due to improper fit, worn-out seals, or strap tension. Make sure your mask size is correct and straps are adjusted evenly for a snug, comfortable seal.

How do I get a better seal with my Torxup mask?

Position the mask over your face, adjust both straps evenly, and check for gaps. Use interactive fitting tips for fine-tuning—ensure the nose bridge and chin areas are sealed and re-adjust as needed.

What causes leaks after a few hours of use?

Long-term leaks can result from movement, mask slippage, or sweat breaking the seal. Regular strap checks and cleaning the seal area before each wear can prevent mid-use leaks.