Quick Pre-Job CoreMask Checks: Straps, Seal & FlowCore Guide

In This Article

- Perform your CoreMask pre-job check every morning without exception.

- Inspect all straps for elasticity, damage, and fit precision.

- Always conduct both negative and positive pressure seal tests.

- Evaluate the condition of FlowCore pads daily—replace if needed.

- Use a consistent checklist and document each check for audit trails.

- Follow expert-recommended maintenance and replacement cycles.

- Train with visual tools and mirror techniques for accurate fit alignment.

Why Pre-Job Checks Matter for Respiratory Safety

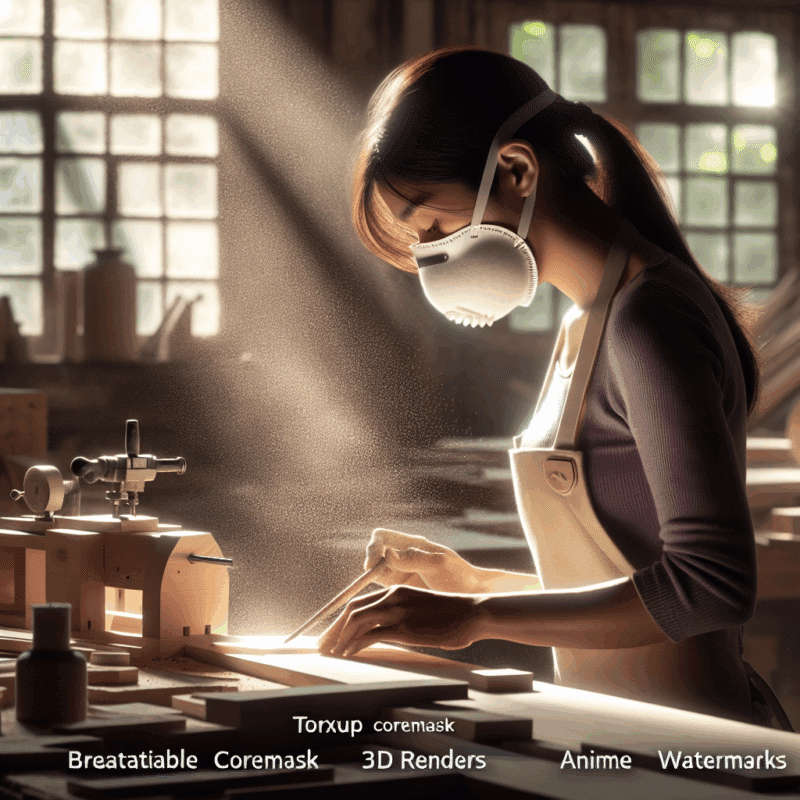

Set the Standard Before You Start

The importance of conducting a CoreMask pre-job check cannot be overstated. Before any shift, workers must verify that their respirators, including all CoreMask components, are in optimal condition. This critical routine ensures both safety and compliance with health standards. Skipping these checks, even occasionally, increases the risk of exposure to hazardous substances. Therefore, making the CoreMask pre-job check a habit is a fundamental responsibility in any industrial setting.

Inspecting Your CoreMask Straps

What to Look for and How to Adjust

Start your CoreMask pre-job check by thoroughly examining the straps. Look for signs of fraying, stretching, or cracking. Any material defects compromise the mask’s fit and, ultimately, your safety. Each strap should exhibit consistent elasticity and exhibit no resistance irregularities when stretched.

Tighten or loosen the straps to ensure a snug yet comfortable fit around the face. Poor strap adjustment can lead to air leakage, which effectively nullifies the mask’s protective function. Alignment also matters—symmetrical strap tension ensures balance and a tight face seal.

Prior to every shift, slightly stretch each strap to confirm elasticity, then reset to your preferred tightness. In case any strap shows noticeable wear or stiffness, replace it immediately. Remember, strap inspection is your first line of defence in a high-risk working environment.

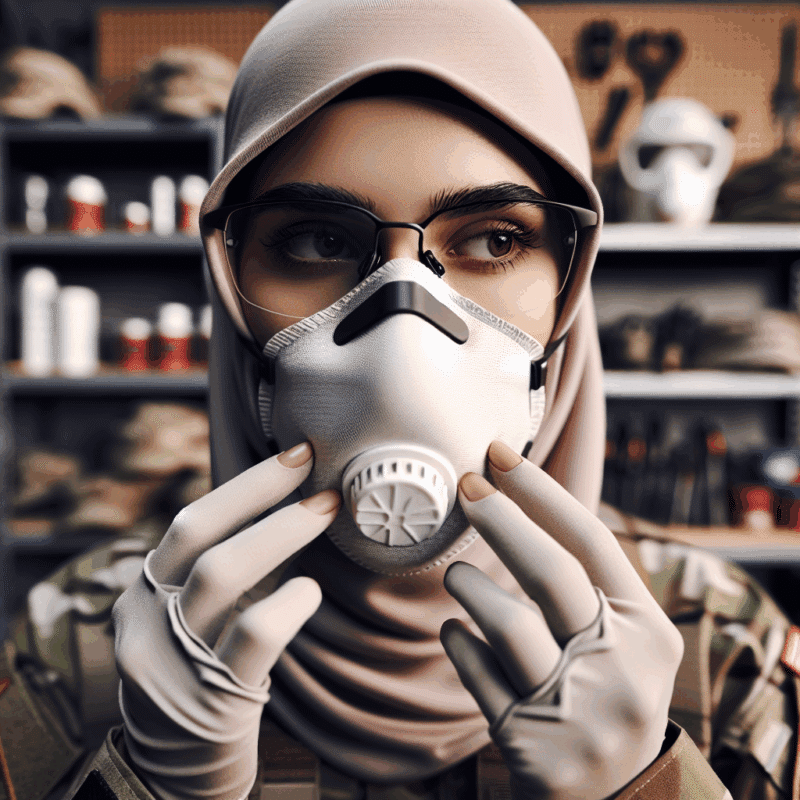

Testing the Seal: Making Sure You’re Protected

Inhale, Exhale, and Adjust

Seal testing during a CoreMask pre-job check ensures the mask interfaces correctly with the user’s face. Begin with a positive pressure test: cover the exhalation valve and exhale gently. If the mask bulges slightly without air escaping, the seal is intact. Follow with a negative pressure test by covering the filter inlets and inhaling. The mask should collapse slightly onto the face and remain so momentarily.

If either test fails, readjust the mask and repeat. Sometimes, obstructions like facial hair or skin oils may affect the integrity of the seal. Always verify the area around the chin and nose bridge for gaps. These micro-leaks can render the mask ineffective under real-world conditions.

Incorporating these two tests into every CoreMask pre-job check dramatically reduces the likelihood of air leakages. As simple as the process is, it is vital and should become second nature to any CoreMask user.

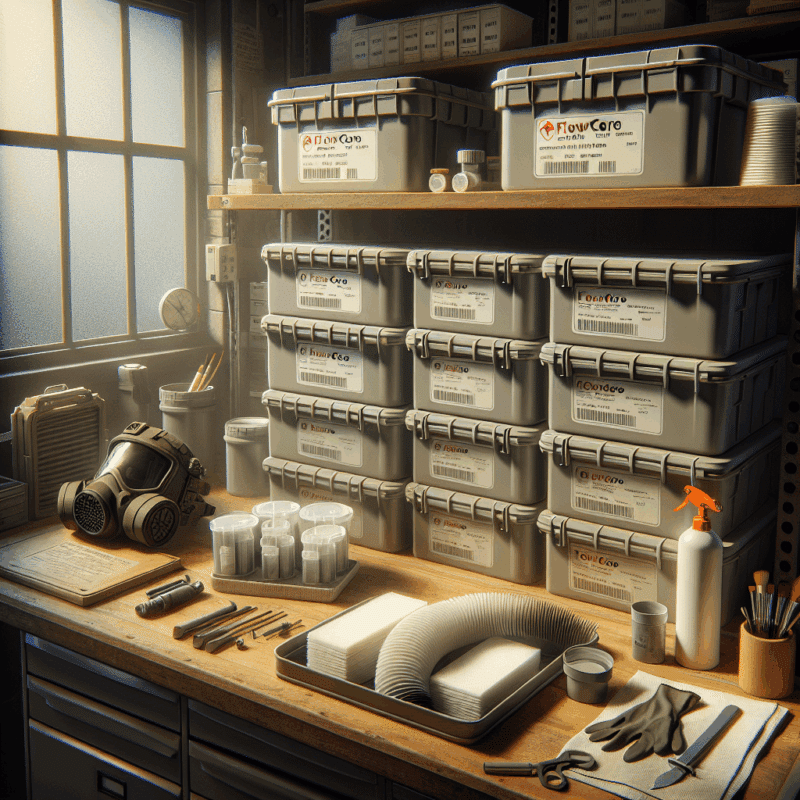

Understanding and Checking FlowCore Pads

When to Replace and Why It Matters

FlowCore pads are an essential element in your respiratory protection system. As part of your CoreMask pre-job check, ensure the pads are clean, dry, and unobstructed. Dust accumulation and moisture retention can reduce airflow efficiency, leading to respiratory discomfort or even hazard exposure.

If the pads exhibit a discoloured, worn, or clogged appearance, they must be replaced immediately. Flow reduction not only impairs breathing ease but also affects the mask’s positive and negative pressure performance during testing.

Understand manufacturer guidelines on pad lifespan and storage. Store new FlowCore pads in dry, temperature-stable environments, and never reuse them if they show wear. Consistent pad inspection ensures not just function, but long-term durability of your CoreMask equipment. For more information on filter care standards, refer to Understanding P3 filter safety and applications.

Common Mistakes During Pre-Job Mask Checks

How to Avoid Errors that Reduce Protection

Despite best intentions, many workers fall prey to common mistakes in their CoreMask pre-job check. One frequent error is rushing the process or skipping steps, especially when under time pressure. Another issue is improper strap adjustment due to a misunderstood snugness standard—tight is not always right.

Moreover, neglecting the FlowCore pad condition during inspection increases risk, as does failing to test the seal in real-time. Users often focus purely on visual checks, ignoring functional checks that reveal subtle issues. Finally, overreliance on previously adjusted settings leads to complacency, assuming the fit hasn’t changed overnight.

Avoid these traps by approaching the CoreMask pre-job check with full engagement. Use a printed checklist to prevent omissions and refresh training bi-annually. Companies should integrate mock inspections into safety drills, reinforcing correct technique. See our full internal protocol guide at Learn more about Dust Mask & Respirator Safety Essentials.

Tips for Getting the Best Mask Fit

Size, Seal, and Strap Symmetry

Optimising fit is arguably the defining part of the CoreMask pre-job check. Select the mask size that best aligns with your facial dimensions. Ill-fitting masks can’t achieve a full seal, even with flawless straps and pads. CoreMask models come in standard sizing, but consult fitting guides if in doubt.

Once you have the correct size, focus on ensuring even strap tension. Unevenness will result in leakage risk near the jaw or cheekbones. It’s also important to verify the chin cup and nose area for flush positioning. Minor adjustments in these areas greatly influence sealing efficacy.

Training in front of a mirror—or ideally, using a buddy system—helps you cross-check correct placement. Wearing the same hairstyle or facial hair configuration consistently also assists in reproducing consistent sealing results. Incorporate these elements systematically into your daily CoreMask pre-job check.

Visual Guide to a Complete Pre-Job Check

Steps You Can Follow Every Morning

Creating a visual checklist for your CoreMask pre-job check enhances memory retention and consistency. Follow this sequence for optimal safety:

- Start by washing your hands thoroughly to avoid contamination.

- Inspect the mask shell for cracks or surface blemishes.

- Examine both straps. Stretch them gently and check for elasticity.

- Fit the mask over your face and secure the straps evenly.

- Conduct the positive and negative pressure seal tests.

- Check the FlowCore pads for blockages, moisture, or discolouration.

- Observe for any sensation of airflow around the edges while breathing.

- Make adjustments as necessary or replace faulty components immediately.

By habituating these steps, you build muscle memory that enforces best practices. Company supervisors should also audit random checks monthly to maintain standards. View our instructional video for real-world demonstrations: Key 2025 product safety regulation changes in the EU.

When to Replace the CoreMask or Components

Know the Signs of Wear

Even with meticulous care, CoreMask components degrade over time. Signs that indicate a need for replacement include visible tears in the seal lining, hardened or limp straps, and persistent airflow anomalies regardless of adjustments. If the mask repeatedly fails seal tests, it should be decommissioned.

Another smart strategy is calendar tracking. Note the date of first use for each CoreMask and its FlowCore pads. Set reminders for component rotation every three months or sooner if in high polluting environments. Durability is also linked to storage practices; avoid leaving the mask in direct sunlight or high-humidity zones.

Refer to manufacturer maintenance cycles and always document each CoreMask pre-job check. Archival logs are particularly useful for identifying patterns leading to premature failure. For deeper insight on replacement guidelines, see Read a related article.

What the Experts Recommend

Industry Best Practices on Filter and Strap Checks

Occupational health experts continuously emphasise the value of systematic CoreMask pre-job checks. According to Health and Safety Executive (HSE) recommendations, respiratory protective equipment (RPE) should be tested pre-use and periodically audited for compliance. Experts stress particular attention to the consistency of the face seal and condition of filters and valves.

In workplace audits, failure points often trace back to overlooked wear in elastic components or improper donning technique. To combat this, many industry leaders incorporate augmented reality (AR) overlays during training sessions to illustrate fit anomalies in real time.

Experts further recommend pairing daily CoreMask pre-job checks with weekly deep-clean protocols. This layered approach helps not only with user safety but also extends component life. Above all, regular refresher courses must be mandated across all teams exposed to airborne hazards.

FAQs on Using and Inspecting Your CoreMask

Community’s Top Questions Answered

Q1: How long should a full CoreMask pre-job check take?

When done correctly, the full procedure should take approximately 3 to 5 minutes. Rushing the process invites error.

Q2: Can you reuse FlowCore pads after cleaning?

No—FlowCore pads are single-use for optimal performance. Washing them degrades integrity and breathing efficiency.

Q3: What is the best way to store a CoreMask?

Store flat in a clean, dry locker. Avoid moisture and extreme temperatures. Use a sealed plastic bag only if dry.

Q4: Can I wear glasses with a CoreMask?

Yes, though a proper seal must still be achieved. Adjust strap tightness and test with your glasses on during the seal check.

Q5: Is facial hair a problem?

Yes. Facial hair disrupts the seal. Users should be clean-shaven in the mask-seal area for best protection.

“A well-executed CoreMask pre-job check is not just a protocol—it’s your daily shield against workplace danger.”

Checklist Summary and Final Reminders

Responsibility for health and safety begins with preparation. The daily CoreMask pre-job check ensures that each team member enters their shift ready and protected. It only takes minutes, but those few minutes could mean the difference between harmless exposure and hazardous contamination.

Before entering any controlled or polluted environment, remember the core sequence: inspect, adjust, test, and confirm. Make this habit routine, and reinforce adherence through supervision. The effectiveness of your CoreMask—and your overall personal protective equipment—depends on this crucial step being executed without compromise.

Great guide on quick-pre-job-coremask-strap-seal-flowcore-check-guide – Community Feedback

How do I check my CoreMask straps before starting work?

Ensure the straps show no tears or fraying. Adjust both upper and lower straps so the mask sits snugly. Avoid twisting and check that buckles are working for a secure fit without discomfort.

What is the best method for testing mask seals?

Place the CoreMask on your face and fasten the straps. Inhale and exhale sharply—if you feel air leaks around the seal, readjust the mask and straps until the seal is firm and leaks stop.

When should FlowCore pads be changed?

Change FlowCore pads whenever breathing resistance increases, contamination is visible, or after the recommended service life. Always use clean hands to inspect and swap filters for best respiratory protection.