How to Quickly Swap FlowCore When Breathing Gets Harder

In This Article

- Swap FlowCore filter when breathing becomes difficult or airflow feels restricted.

- Inspect filters before and after each shift for visible signs of wear.

- Store unused filters in sealed packaging away from moisture and dust.

- Follow precise steps to remove and install filters to avoid seal failures.

- Never attempt to reuse disposable FlowCore filters under any condition.

- Adopt a scheduled replacement programme based on work type and contaminant level.

- Use only compatible FlowCore filters as specified by the manufacturer.

- Keep internal resources, such as filter logs and training manuals, routinely updated.

- Order from verified suppliers and double-check packaging for authenticity.

What Is a FlowCore Filter and Why It Matters

Overview of FlowCore Technology

FlowCore filters are advanced multilayer filtration units commonly used in respiratory protection systems across industries like construction, painting, welding, and chemical processing. Known for their high-efficiency particulate absorption and low resistance breathing design, these filters are pivotal in ensuring workplace safety. The main purpose is to filter out hazardous airborne particles, toxins, and vapour-based contaminants.

When Is the Right Time to Swap Your Dust Mask Filter?

These filters use engineered fibre arrangements and activated filter media, structured to maintain efficient airflow while capturing fine particulates and aerosols. Over time, however, particulates begin to clog the fibre network, which can lead to increased breathing resistance. When this happens, it’s time to swap FlowCore filter components.

Common Signs the Filter Needs Changing

Breathing Resistance and Visual Indicators

Breathing resistance is the foremost and most personal indicator that it’s time to swap FlowCore filter elements. If you find yourself straining to breathe while wearing a respirator you previously used comfortably, it is likely the filter media has reached the limit of its capacity. Prolonged use of clogged filters stresses the lungs and may allow contaminants to circumvent less efficient airflow paths.

Step-by-Step Guide: How to Change a FlowCore Filter

Aside from increased resistance, examine the filter for visible signs of use. A darkened or uneven surface, dust accumulation, or spongy texture are all red flags. Some FlowCore models also include integrated change indicator strips on the filter casing. Consult your equipment guide for where this indicator is located.

“Any noticeable change in breathing ease or airflow consistency is a key signal—it’s time to swap FlowCore filter at once.”

When to Check Your Filter During Projects

It is best practice to inspect the filter both before and after each shift, especially in environments with high particulate emissions or low ventilation quality. If you’re working with substances like silica dust, chemical vapours, or spray paints, hourly checks might be warranted. Regular inspection ensures the filter operates efficiently without compromising your health.

Understanding Difficulty Breathing in Your Respirator

If your project has started to span multiple days or if the nature of tasks varies throughout the day, assign regular intervals to assess airflow quality. Consistent maintenance helps identify when to swap FlowCore filter mechanisms before they become a liability. Always maintain a log of filter changes for audit and tracking purposes.

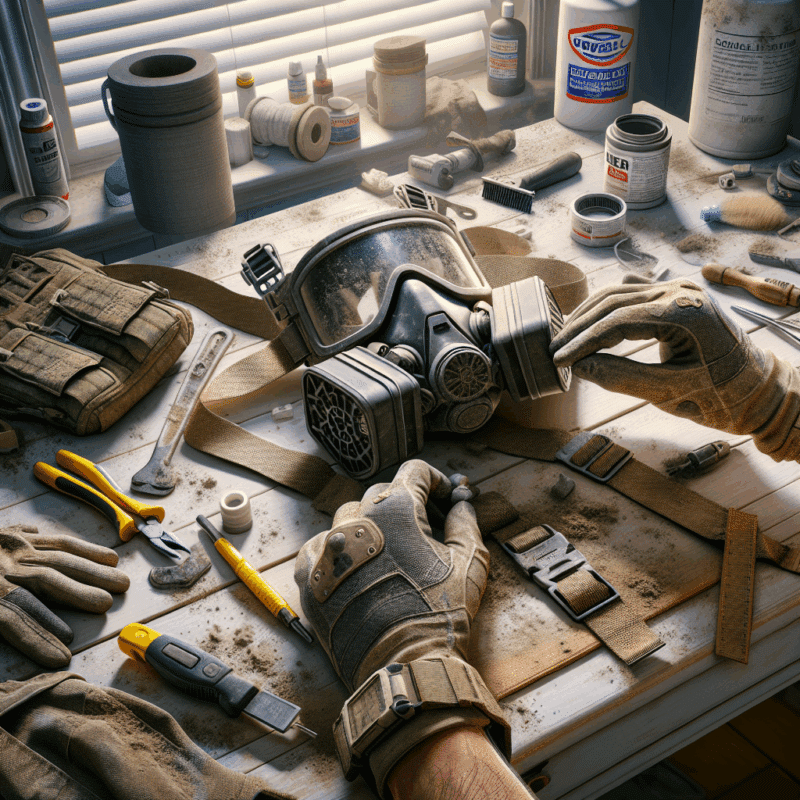

How to Properly Remove the Used Filter

Before removing a used FlowCore filter, it’s essential to prepare a contaminant-free workspace. Start by donning gloves and, if applicable, eye protection. Place the respirator on a clean, flat surface to avoid contamination. Hold the respirator securely and gently twist off or slide the filter cartridge as per the manufacturer’s specification.

DIY Guide: Changing Your Mask Filter with Ease

Avoid forceful removal as this can damage the filter casing or the respirator’s connector. If the filter is stuck, examine for built-up debris or dried particulates around the threading. Dispose of the used filter immediately in a sealed plastic bag, especially if it was exposed to hazardous substances.

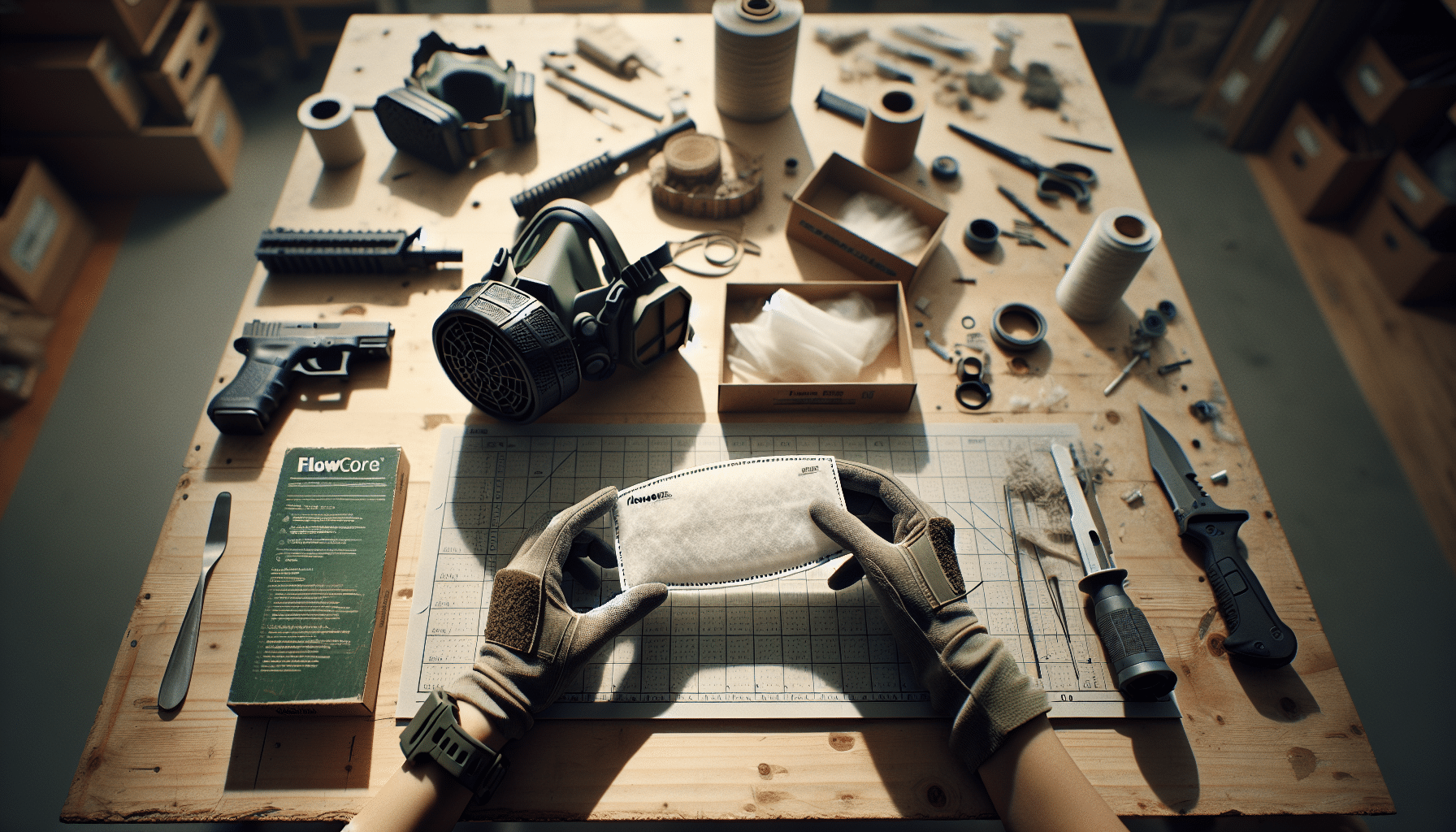

Steps to Correctly Install the Replacement

To install a new FlowCore filter, first ensure compatibility with your respirator model. Check the product code and date of manufacture. Insert the filter by aligning the contact notches or threads—follow directional markings on the cartridge to avoid misalignment. Tighten until there is no lateral movement but avoid overtightening which can strip seals or deform the tubing.

Quick Tips for an Efficient FlowCore Filter Swap

After installation, conduct a positive and negative pressure check. Block the exhalation valve and exhale gently to see if air leaks occur from the filter seal. Similarly, block the filter intake and inhale to test suction. Any leakage could indicate an incorrect installation or defective filter. Only begin work once the seal is confirmed reliable.

Tips for Storing Spare and Used Filters

Proper storage extends the shelf life of spare FlowCore filters and prevents cross-contamination between new and used units. Always keep replacement filters sealed in their original packaging until needed. Store them in a dry, dust-free cabinet at temperatures within the recommended range, usually between 5°C and 25°C.

How to Recognize When Your Dust Mask Filter Needs Replacement

For used filters not immediately discarded (such as those temporarily stored for testing), place them in an airtight, clearly labelled container indicating date and exposure type. Never store used and new filters together—this increases the risk of mix-ups and contamination. Routinely check stored filters for expiration dates or packaging damage.

Safety Benefits of Timely Filter Change

The most immediate benefit of timely filter replacement is optimised respiratory health. Users consistently report reduced fatigue and increased alertness when airflow is unimpeded. Swapping old filters also ensures contaminants aren’t re-circulated or bypassed due to clogging or seal weakening.

Troubleshooting: Why Your Mask Feels Hard to Breathe Through

Furthermore, adhering to a regular filter swap schedule can extend the lifespan of your respirator unit. Filters that are left too long may release trapped moisture or degrade internally, which can damage valve components and housing units. From a compliance standpoint, timely filter replacement ensures that your PPE adheres to occupational safety standards such as HSE, EN 143 and ISO 16975.

Mistakes to Avoid While Handling Respirator Filters

Improper practices during filter changes can compromise the entire PPE system. One of the most common errors is touching filter media with bare hands, unintentionally transferring contaminants. Always handle filters by their outer casing. Never attempt to clean or reuse disposable FlowCore filters—this defeats their safety design.

Replacing Your FlowCore Pad: A Step-by-Step Process

Another crucial mistake is skipping compatibility checks. Not all FlowCore cartridges fit every respiratory system. Using a mismatched filter can create uneven seals and poorly filtered airflow, jeopardising your safety. Finally, storing filters in wet or dusty conditions diminishes their effectiveness before use. If you detect a chemical odour or dampness from a stored filter, discard it immediately.

Recommended Products and Reordering Links

Ensuring you have an appropriate stock of FlowCore filters is crucial for operational continuity. Leading products include the FlowCore X-Air, FlowCore SilentGuard P100, and FlowCore Dual-Lock CarbonVariant. These models cater to a variety of applications from heavy industrial use to fine aerosol-laden environments.

You can find internal guidance on recommended filter pairings in our Phase II Respirator Training Manual. For quick reordering or bulk purchases, visit Learn more about Respirator and Dust Mask Safety for DIY or consult our restocking planner at Read a related article. For additional information regarding international distributors and specs sheets, refer to Understanding breathlessness symptoms and causes and the regulatory compliance database at Cross-border compliance with smart AI solutions.

Conclusion: Keep Breathing Easy and Work Safe

[CONCLUSION_CONTENT]

To protect your lungs and prolong the life of your equipment, always prioritise proper maintenance protocols. Taking the time to swap FlowCore filter components regularly not only enhances immediate safety but also reinforces a culture of responsibility and preparedness across your team. By following the best practices outlined in this guide, you’ll ensure greater air quality, prevent unplanned downtime, and maintain full compliance with industry standards.

Great guide on quick-guide-flowcore-swap-breathing-harder – Community Feedback

How do I know when to swap my FlowCore filter?

If breathing through your mask feels noticeably harder or resistance increases, it’s time to replace the FlowCore filter. Visual indicators, such as discolouration or clogging, also signal replacement is due.

How do I change a Torxup FlowCore filter?

Remove the mask gently, unclip the filter housing, and replace the used FlowCore pad with a fresh one. Secure the housing and ensure a proper fit before resuming work.

Why does a clogged mask filter make breathing tough?

A clogged FlowCore filter restricts air flow, increasing breathing effort. This occurs as dust accumulates, blocking pores. Timely replacement restores easy, safe breathing and optimal mask protection.