How to Fit CoreMask Under Hard Hats – Trade-Compatible Guide

In This Article

- Master the checklist for CoreMask and helmet compatibility before wear.

- Use the right strap configuration to balance seal and comfort.

- Re-test respirator fit after any task break or helmet adjustment.

- Engage in formal fit testing annually, or when conditions change.

- Invest in maintenance; small damages degrade protection fast.

Why Proper Fit Matters for PPE Safety

Health risks of poor respirator placement

To fit CoreMask under hard hat effectively is to protect your lungs and health from exposure to hazardous airborne particles. Respirators like CoreMask are engineered to filter out dust, fume, and harmful particulates, but a poor fit can nullify all those protective qualities. When the seal breaks—either from helmet interference or incorrect strap positioning—contaminants seep in. This can lead to acute respiratory issues, or worse, long-term pulmonary disease.

Many tradespeople underestimate the subtle impact of incorrect placement. Even small gaps caused by helmet pressure can lead to leaks. Occupational health studies confirm that improper respirator use remains a top cause of avoidable ill health within trade sectors. Ensuring a close, unbroken seal should be a non-negotiable foundation of your workday routine.

Luckily, today’s PPE is evolving. Products like CoreMask are designed with integrated features specifically for hard hat compatibility. That said, even the smartest equipment relies on smart usage. The process of how you fit CoreMask under hard hat components directly influences filtration efficiency. Choose diligence over assumption.

What Is the CoreMask and Why It’s Trade-Friendly

Key comfort and sealing features

CoreMask is a reusable half-face respirator built for long wear across demanding environments. What sets it apart from disposable masks is its silicone facepiece, ergonomic design, and easy maintenance. Whether you’re grinding steel or pouring concrete, a CoreMask provides consistent filtration without sacrificing comfort.

Key features include an adjustable harness system, low-profile filters, and repositionable straps that reduce interference with helmet shells. Unlike rigid half masks, CoreMask flexes with facial movement, keeping the seal intact without creating pressure points. Tired of discomfort leading to unsafe removal? CoreMask solves that by enabling a snug, breathable fit all day.

Another reason trades favour CoreMask is its adaptability. The harness accommodates hard hat suspension with minimal adjustment. Certain models even incorporate a drop-down design, letting you lower the mask temporarily without full removal—a compliant feature for site settings where communication is crucial.

“The CoreMask was a game-changer on our offshore job. Finally, a mask that fits right under the hard hat and doesn’t mess with my gear.” – Site Supervisor, Aberdeen

Checklist: Helmet & Mask Compatibility

Before attempting to fit CoreMask under hard hat safety systems, confirm that your gear is compatible. Here’s a pre-fit checklist:

- ✔ The hard hat has an adjustable, 4- or 6-point suspension system.

- ✔ The CoreMask model includes a flexible head harness (not a rigid cradle).

- ✔ The helmet profile is standard industrial (Class C, G, or E), not bump caps or specialised gear.

- ✔ You are not wearing over-ear defenders that conflict with the mask straps.

- ✔ Facial hair is limited, as even small stubble may compromise the mask seal.

- ✔ The job does not require simultaneous use of face shields that could reposition the helmet weight.

If all items check out, you’re ready to proceed. Learn more about Respiratory Protection for Trade & DIY

Preparing Your Hard Hat for Mask Fit

Proper helmet preparation ensures easier mask integration. Begin by inspecting your hard hat for wear and tear. Cracked shells or warped suspension can alter mask strap pressure and impact fit. Replace helmets according to manufacturer guidelines—especially if they’ve been dropped or exposed to extreme temperatures.

Next, loosen the suspension system. Many tradespeople forget that newer helmet models allow micro-adjustments to avoid downward pressure on the respirator bridge. Set the helmet height one level higher if the suspension digs into the CoreMask area.

Do a dry run: put on only the CoreMask, adjust the seal, then add the hard hat without shifting the mask. You’ll be able to fine-tune strap flatness against the nape and crown zones. This step alone dramatically reduces fit failures later in the day.

Adjusting CoreMask Straps for Seal & Comfort

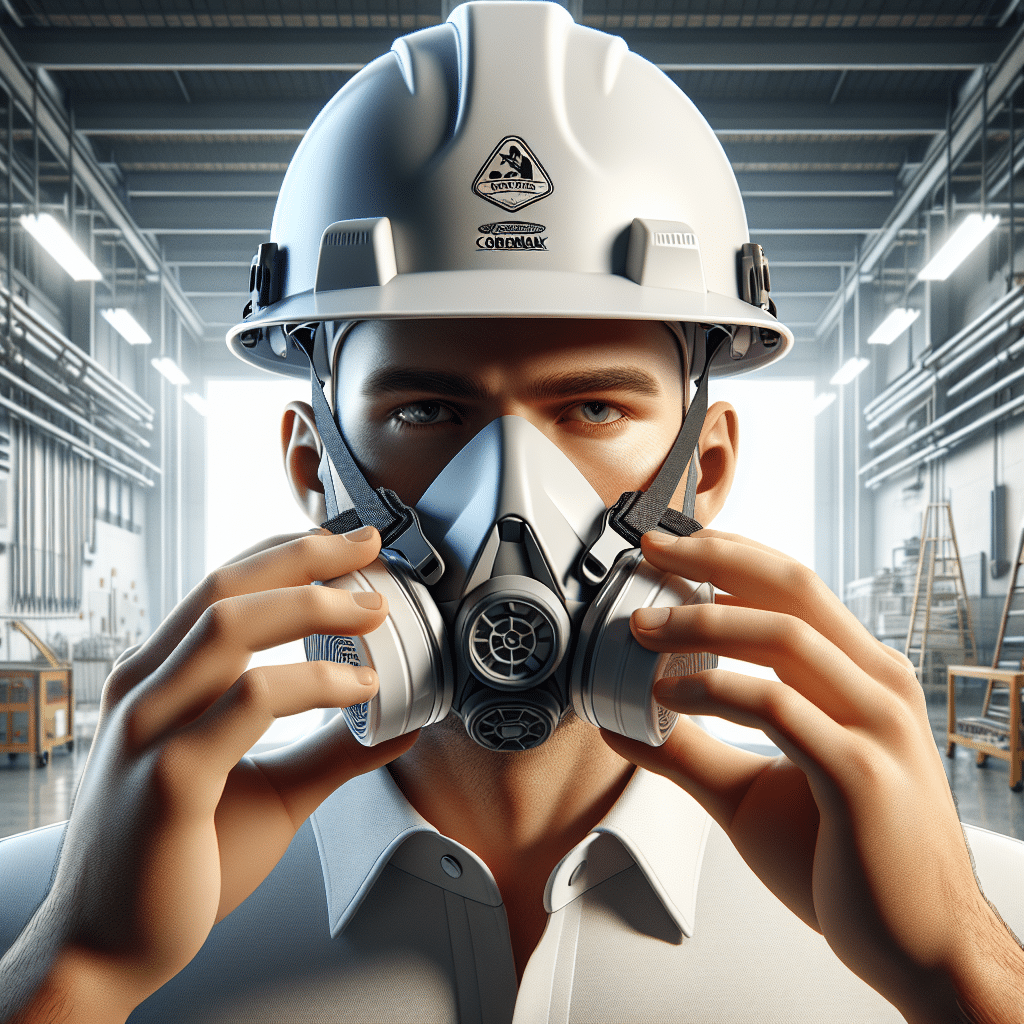

To correctly fit CoreMask under hard hat use, start with clean hands and ensure all components are in good condition. Begin by extending the mask’s lower strap and placing the facepiece over your nose and chin. Pull the upper straps over your head and settle them just below your helmet suspension.

Crucially, tighten the straps evenly from bottom to top—but do not overtighten. Over-compression causes discomfort and early fatigue. The strap material should lie flat beneath the helmet cradle, without creasing or twisting. Any strap folds can shift throughout the workday, loosening your seal.

Confirm that the exhalation valve is not obstructed by inner helmet features. If necessary, rotate or shift the helmet slightly to prevent contact. Finally, perform a positive and negative pressure test to confirm there are no leaks before entering your work zone. Read a related article

Fitting at Job Sites: Common Scenarios

Fitting CoreMask under hard hat protection can be straightforward in a controlled environment, but what about actual job sites? Common scenarios require varied approaches:

Scenario A: Constrained Confined Spaces

In tight tunnels or underdeck environments, visibility is reduced. Practise donning PPE in such spaces during induction days. Use a helmet-mounted torch so you can double-check strap position once inside.

Scenario B: Cold Weather Environments

Layering under the helmet can ruin mask placement. Opt for a balaclava designed with mask cut-outs to prevent shifting. Always check fit post-layering.

Scenario C: Quick Access Task Switching

When switching between mask-on and mask-off tasks, use CoreMask’s drop-down feature. Don’t tilt the helmet forward to remove the respirator—it destabilises both kit integrity and safety compliance.

Avoiding Air Leaks While Wearing PPE

Even minor leaks can nullify your respirator’s protection. You can fit CoreMask under hard hat gear impeccably, but site activity and helmet motion introduce new variables. Here’s how to proactively avoid leaks:

- ✔ Re-check strap tension after lunch breaks or helmet swaps.

- ✔ Avoid scratching your face or adjusting the mask mid-task without a reseal test.

- ✔ If a coworker notices a squashed or crooked mask, refit immediately.

- ✔ Use field mirrors mounted at stations for quick checks.

- ✔ Document incidents of reported leakage in your PPE logbook.

Remember: no one gets it right 100% of the time. But learning to self-regulate your fit habits increases your long-term resilience in hazardous trades.

Test Fit: How to Know It’s Sealed Correctly

Every time you fit CoreMask under hard hat gear, a fit test is mission-critical. Here’s how to run a proper self-assessment:

1. Positive Pressure Test

Cover the exhalation valve with your palm and exhale gently. If the mask bulges slightly and you feel no escaping air, you have a good seal.

2. Negative Pressure Test

Plug the inhalation openings (depending on model design) and inhale. The mask centre should collapse slightly onto your face. No air should rush in.

Fail either test? Refit it all. Get in the habit until it becomes muscle memory. This protocol is aligned with HSE recommendations for half-face respirators. Safety guidance on PPE under hard hats

Maintaining PPE Performance Over Time

Perfect fit today doesn’t mean perfect fit tomorrow. To retain your ability to fit CoreMask under hard hat setups efficiently, maintain all components weekly:

- ✔ Wash the facepiece with mild solution weekly.

- ✔ Inspect the valve membranes for micro-tears.

- ✔ Replace filters based on exposure levels—not just visible dirt.

- ✔ Store the entire set in a PPE bag, separate from tools.

Wear and tear isn’t an excuse for poor performance. It’s an indicator that your PPE is doing its job. But you must meet it halfway with care and attention.

Industry Standards for Respirator Fit

The fit CoreMask under hard hat compatibility is mentioned in various occupational safety guidelines. In the UK, the Health and Safety Executive (HSE) requires employers to ensure tight-fitting RPE (Respiratory Protective Equipment) is face-fit tested for each user.

This includes testing for overlap with other headgear. Hard hats can affect negative pressure mask efficiency due to movement or downward compression. That’s why manufacturers like CoreMask design their gear with EN 140 compliance, ensuring suitable compatibility for a wide range of certified helmets.

All fit testing must be renewed annually or when significant facial changes occur. Growth of facial hair, weight fluctuation, or even dental work can alter the mask’s sit. Refer to accredited fit test programmes or consult experienced safety officers to stay in compliance. Managing compliance for safety equipment

Conclusion: Trade Smarter, Breathe Safer

To fit CoreMask under hard hat gear effectively is to treat your health as a core component of your skillset. Beyond tools and technique lies your respiratory safety—a vital shield shaped by small, consistent habits. From micro-adjustments to regular testing, integrating CoreMask properly into your PPE line-up isn’t just smart; it’s essential to long-term career viability.

Mastering this setup helps you maximise comfort without compromising protection. It’s a daily discipline that deserves the same attention as checking your harness or inspecting your tools. When you trade smarter, you breathe safer.

Great guide on fit-coremask-under-hard-hat-guide – Community Feedback

Can you wear CoreMask under a hard hat?

Yes, the CoreMask is designed for low-profile comfort and secure fit beneath hard hats, safety helmets and most trade headgear without sacrificing protection.

How do I prevent mask leaks with safety gear?

Adjust the CoreMask straps to create a snug seal. Ensure the mask sits below the helmet harness, and check for leaks by exhaling to feel for airflow around the edges.

Is CoreMask suitable for construction and site PPE?

Absolutely, CoreMask meets UK standards and is compatible with most helmets and visors. Its design is ideal for trades requiring both respiratory and impact protection.