FlowCore & ProDefend Pad Lifespan: When to Replace Filters

In This Article

- Always inspect filters visually before and after use for early signs of saturation

- Respect the 1–2 week replacement rule, especially in high-particulate environments

- Use airtight storage to prevent degradation outside of active use

- Carbon filters lose effectiveness more rapidly in chemical-rich environments

- Track usage hours to build a personal filter lifespan profile

- Purchase only from verified suppliers to ensure filter integrity

- Differentiate between particulate and chemical tasks to optimise filter type

- Stay informed through community resources and manufacturer recommendations

- Proper planning avoids lapses in protection during critical tasks

- Healthy air means proactive filter management—don’t delay replacement

Why Regular Filter Replacement Matters

Keep Your Lungs Safe

The filter lifespan of your FlowCore or ProDefend protective equipment is not simply a matter of product degradation—it’s about safeguarding your respiratory system. Filters play a critical role in capturing fine particulates, allergens, dust, and harmful chemicals. However, as these filters become saturated, their performance deteriorates. Without timely replacement, the pad no longer offers proper respiratory protection, exposing the user to harmful airborne contaminants. Ignoring filter lifespan can lead not only to reduced filtering efficiency but could also result in complete filter failure in extreme cases. By regularly replacing these pads, users ensure they benefit from consistent high-performance outcomes, whether during DIY tasks, sanding, construction, or exposure to allergens.

Recommended Replacement Frequency

Understanding the 1–2 Week Rule

Manufacturers such as FlowCore and ProDefend recommend inspecting filter lifespan every 7 to 14 days, depending on usage intensity and environmental conditions. For light DIY or occasional work, changing the pads every two weeks may suffice. Conversely, if you’re engaged in activities that generate heavier particulate loads—like sawing, insulation work, or prolonged dust exposure—a weekly filter change becomes more appropriate. Remember, this 1–2 week guideline is not arbitrary; it’s based on airflow impact, particle saturation tests, and real-world user data. These intervals are calculated to offer peak protection without compromise. If you’re unsure whether your working environment is ‘light’ or ‘high-intensity’, it’s better to err on the side of caution and lean toward more frequent changes. It’s far better to replace too soon than risk compromised breathing quality. For tasks involving aerosols or chemical fumes, filter lifespan may be even shorter, necessitating daily inspections to ensure optimal safety. Adherence to this timeline ensures consistent performance and prevents unnoticed degradation.

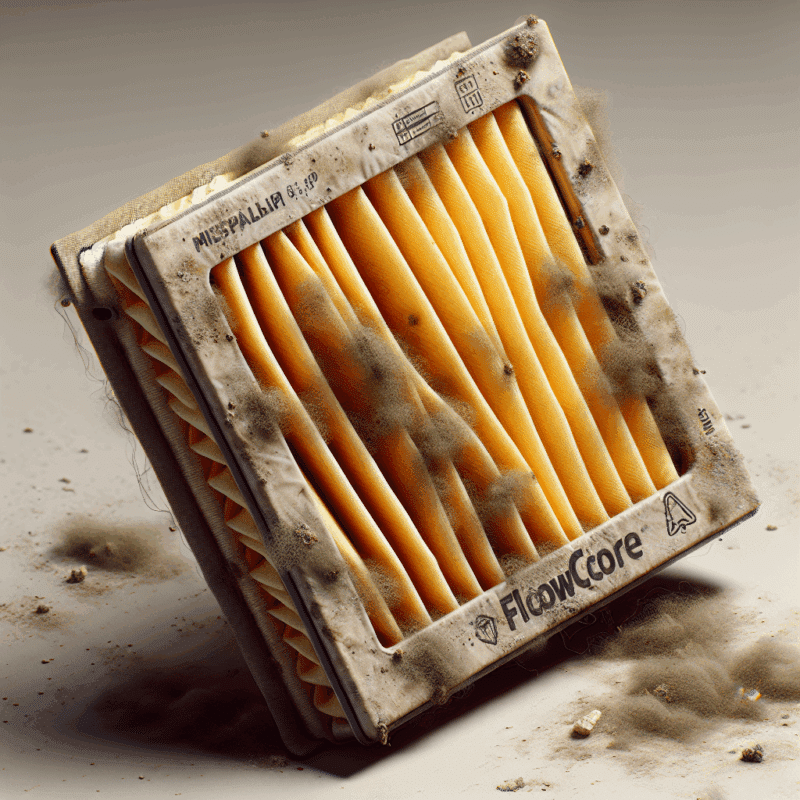

Signs It’s Time to Swap Filters

Don’t Ignore These Red Flags

Spotting signs of diminished filter lifespan can prevent respiratory risks. One key indicator is increased breathing resistance—if you’re struggling to inhale or exhale, your filter may be clogged. Visual inspection is equally important; discolouration, dark debris accumulation, or a musty scent are red flags. Additionally, recurring respiratory irritation such as sneezing, coughing, or throat dryness can suggest that harmful particles are bypassing worn-out filters. You may also notice a hissing sound during air intake, an indicator of compromised filter seal or integrity. If using ProDefend carbon pads, a decrease in odour absorption can signify carbon saturation, rendering the filter ineffective against fumes. Regular inspection is your best preventive measure. If any of these warning signs are present, it’s best to replace immediately rather than wait for scheduled maintenance. Even if the external appearance seems unchanged, internal saturation can silently diminish filtration efficiency.

Factors That Impact Filter Lifespan

From Dust to Humidity

Several environmental and usage factors influence your filter lifespan. High particulate exposure—such as during sanding, plastering, or dealing with insulation—results in faster clogging. Ambient humidity levels can also shorten filter life; moisture causes particulate matter to clump, rapidly reducing airflow and increasing internal resistance. In chemically active environments like painting or varnishing, the reactive compounds can saturate carbon filters faster than under dry, clean conditions. Your breathing rate also plays a role: more active labour leads to more air drawn through the filter, hastening wear. Additionally, improper storage in dusty or humid places can further degrade filter materials before first use. Even infrequent users can experience decreased filter lifespan if storage conditions are not controlled. To maintain optimal performance, it’s crucial to consider all these variables holistically. Doing so helps prevent premature saturation and ensures your filters operate at full efficacy. Learn more about Reusable Dust Mask Maintenance & Protection

Tips to Extend Filter Life

Smart Storage and Use

While filter lifespan has its fixed limitations, proper handling can substantially extend usefulness. First, store your filter pads in an airtight bag or sealed container when not in use—this prevents prematurely absorbing ambient dust particles and moisture. Secondly, only open replacement pads upon actual installation to preserve freshness and prevent contamination. Avoid exposing filters to direct sunlight or heat, as both can weaken materials. When taking breaks from tasks, remove the filter-equipped mask and reseal it if possible. This reduces unnecessary filter exposure. For users cycling between light and heavy duties, rotating between clean and moderately used filters can optimise longevity without compromising on safety. Lastly, keep a maintenance log to track usage hours and replacement dates. Over time, you’ll get a personalised sense of filter lifespan in your specific working environments. These small but deliberate actions can translate into fewer replacements and better ongoing protection.

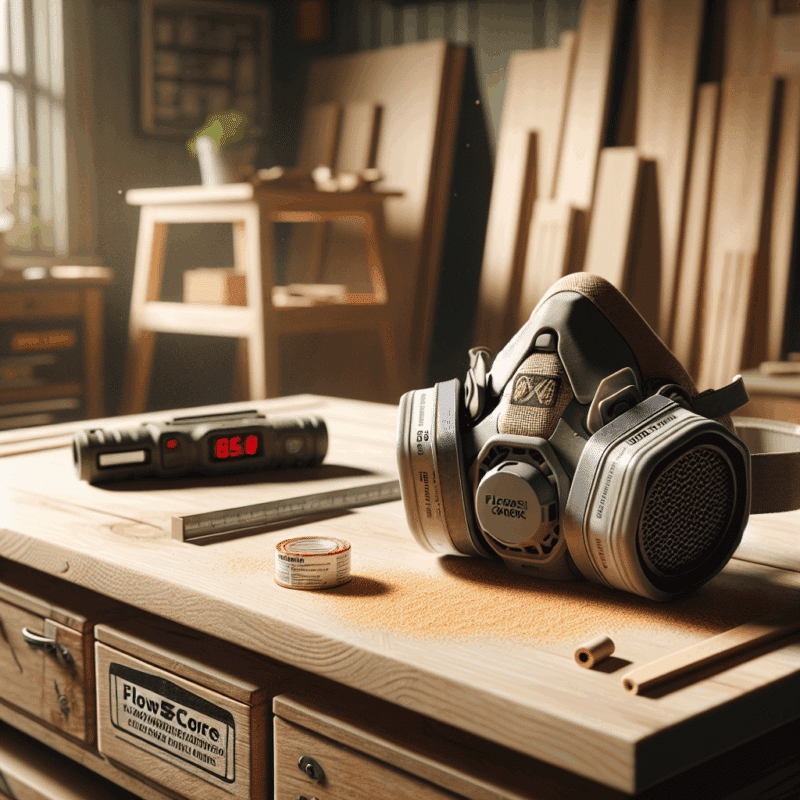

FlowCore Pad Usage Guidelines

Best Practices and Storage

FlowCore filters are engineered for modular flexibility, but their filter lifespan still depends on disciplined handling. Whether using the white particulate-only pads or carbon-infused variants, change frequency depends on observed dirt build-up and airflow degradation. To maximise filter effectiveness, always use the pads within the manufacturer’s recommended timeframes and check before each new application. Store FlowCore pads flat in original packaging, away from temperature extremes. After exposure to high particulate environments, a brief visual inspection post-task can reveal whether earlier replacement is necessary. Using a pre-filter cover can intercept larger debris and extend the usability of the core pad itself. Additionally, batch-labelling pads with usage dates is an efficient method for teams managing multiple masks. Factors impacting filter lifespan and maintenance offers printable templates for this purpose. Practising accountability in usage directly influences safety outcomes and supports filter longevity.

ProDefend Filter Intervals

Carbon vs. Particulate Use Cases

ProDefend filters include two categories: carbon pads for chemical and odour filtration, and particulate filters suited for dust and non-volatile compounds. Each has distinct filter lifespan profiles. Carbon pads generally last 10 to 14 hours in high-exposure situations involving fumes or strong odours. For lighter odour exposure, they may be safe for up to 40 hours, but odour detection intensity provides a good benchmark for replacement. Particulate filters hold up longer under similar durations but must be checked visually for saturation. Do note that mixing the two can result in overlapping wear; for instance, dust may clog the carbon pad prematurely, curbing both gas absorption and airflow. As such, users should categorise tasks and pre-plan filter usage accordingly. Field tests suggest that rotating filters every 10 active hours is a safe average, reducing exposure risk from declining performance. Maintaining separate filters per task type tends to yield better long-term protection outcomes. Read a related article

Real User Feedback

What the DIY Community Says

Within the community of makers, woodworkers, and DIYers, discussions around filter lifespan are vibrant and highly informative. Many users report noticeable airflow reduction after intensive sessions involving sawdust or insulation work, reinforcing the 7–10 day change rule. On ProDefend’s forums, some users reported odour issues after only 8 hours of solvent exposure, highlighting the importance of environmental awareness. Others have praised FlowCore’s double-layer filters, noting improved durability in sawmill environments when used with a pre-filter shield. In online reviews, several enthusiasts even describe labelling their filters with a “used hour” count, helping them gauge future replacement without second guessing. From seasoned tradesmen to weekend tinkerers, the consensus is clear—proper attention to filter lifespan significantly improves health and comfort. User tip compilations found on SEO strategies for compliance-focused sites suggest spreadsheet tracking tools for multi-use filter workflows, which are growing in popularity among professionals managing gear across crews.

“After I started tracking filter lifespan based on active wear time, I stopped getting headaches mid-project. Clean airflow makes all the difference.” — DIY Community Member

Find the Right Replacement Pad

Shop FlowCore & ProDefend

Sourcing authentic replacement pads is crucial for filter lifespan consistency and overall gear functionality. FlowCore and ProDefend offer dedicated stores with detailed listings to match each mask model. If uncertain, cross-reference pad model numbers with your original filter pack. Retail partners also offer bundle packs that align with recommended replacement timelines—ideal for regular users. In many cases, multi-pack purchases offer savings while ensuring you never face a shortage mid-project. Look for replacement pads with sealed packaging and clear expiry dating, and avoid unauthorised third-party sellers where authenticity can’t be assured. When in doubt, contacting customer support for compatibility assurance is worthwhile. Both FlowCore and ProDefend also offer online subscription options for auto-shipments tailored to your usage schedule, helping you maintain optimal filter lifespan without the guesswork. Whether through direct purchase or recurring deliveries, staying well-stocked means staying well-protected.

Conclusion: Breathe Safer with Timely Replacement

In summary, managing filter lifespan isn’t a passive activity—it’s an active investment in your health. Timely filter changes for FlowCore and ProDefend gear keep your lungs protected and ensure optimal tool performance. From understanding usage intervals to recognising visual wear signs, every step in the process contributes to peace of mind and clean breathing. Considering how many variables affect each filter—usage level, environment, humidity—it’s imperative to rely on more than just timeframes. Practising proactive inspection, mindful storage, and proper handling all help extend functional lifespan. Ultimately, awareness and action are your best allies in ensuring each breath taken is a safe one.

Great guide on filter-lifespan-change-flowcore-prodefend-pads – Community Feedback

How often should I change FlowCore or ProDefend pads?

Pads should be replaced every 1–2 weeks for heavy use or when breathing is restricted, the filter looks dirty, or odour breakthrough occurs.

What affects the lifespan of my dust mask filters?

Filter lifespan depends on dust levels, usage frequency, humidity, and correct storage. Pollutant-rich environments shorten replacement intervals.

How can I extend the life of my FlowCore pads?

Store masks dry, avoid excess exposure after use, and replace pads before full saturation to maintain protection and airflow.