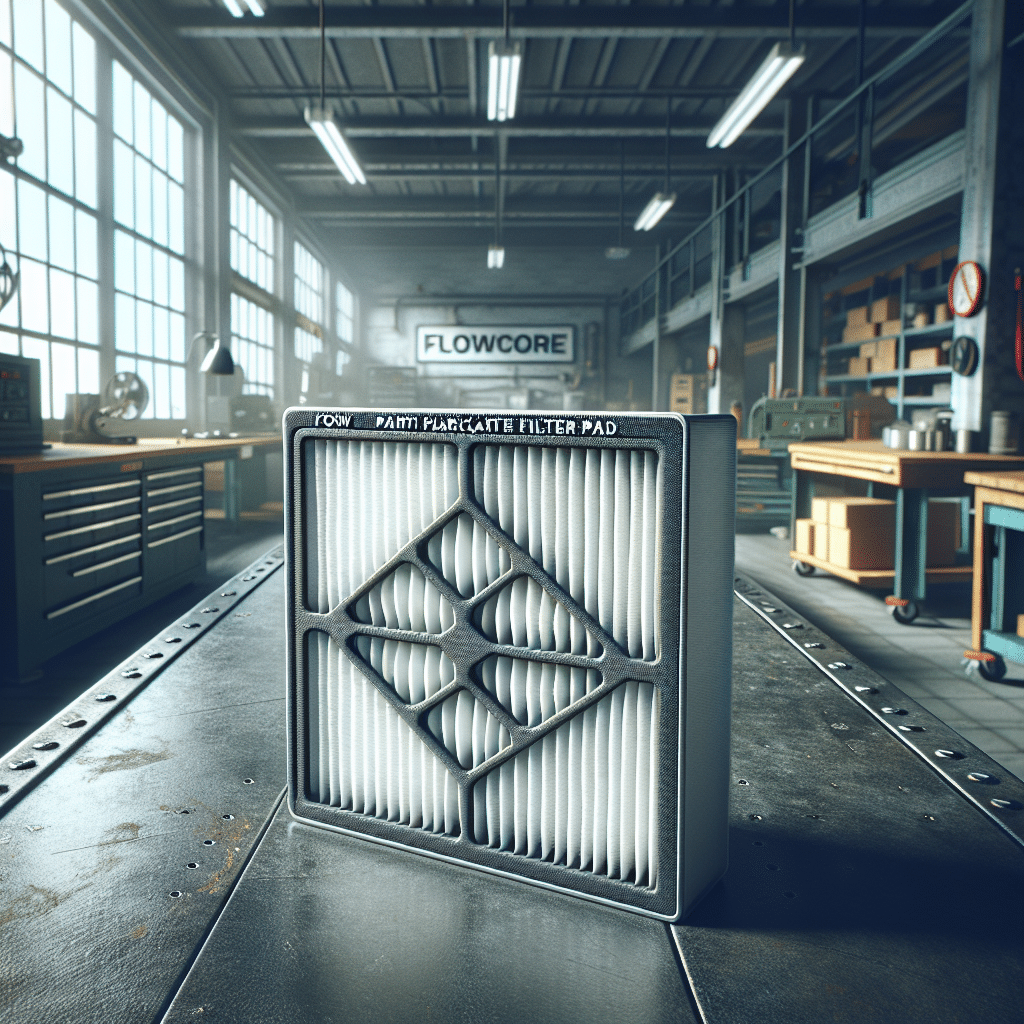

FlowCore Filter Indicators: When To Replace Pads – Torxup Guide

In This Article

- Check the filter indicator before and after each usage session.

- Replace filters at first signs of discolouration, damage, or resistance.

- Store filters in sealed, contaminant-free environments to preserve shelf life.

- Match your replacement schedule with the intensity of your work environment.

- Always use official FlowCore-compatible replacement pads and parts.

- Reference Read a related article for visual guides and maintenance schedules.

- Visit How automation drives product findability for PPE compliance updates and best practices.

Why Filter Indicators Matter

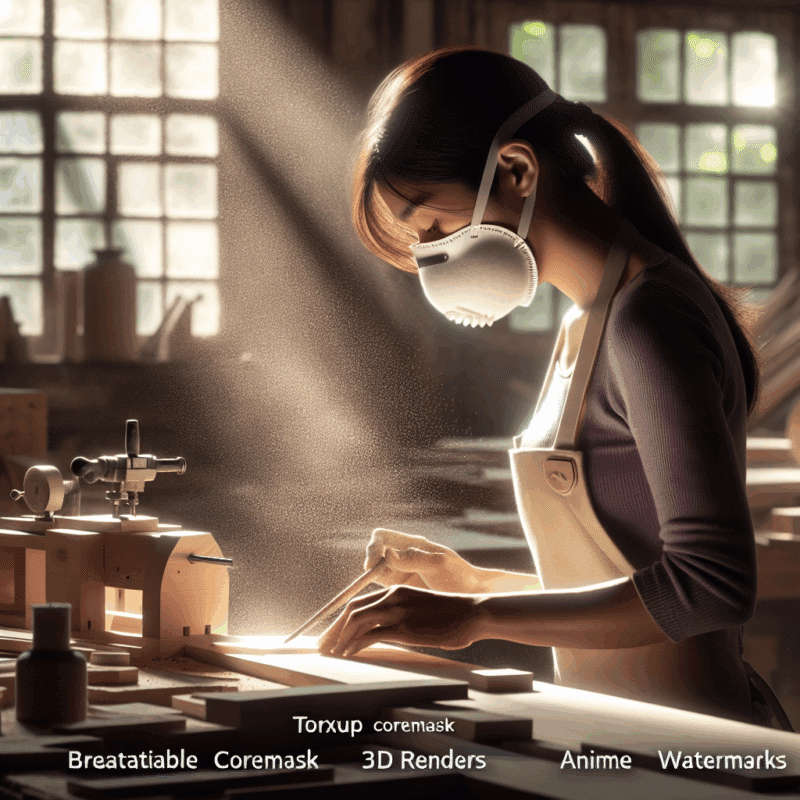

Protecting Your Respiratory Health

The importance of a filter indicator in your FlowCore respirator system cannot be overstated. These devices are essential safety components, designed to notify users when it’s time to replace particulate pads. Whether you’re in industrial surroundings, laboratory environments, or involved in at-home renovations, your respiratory protection hinges on filter performance. A worn or blocked pad doesn’t just lower filtration efficiency—it can become a direct risk to your health.

Filter indicators operate as early warning systems. When used correctly, they prevent users from unknowingly breathing contaminated or unfiltered air. They save lives and reduce long-term health risks like respiratory illness or occupational asthma. Deterioration in filter condition isn’t always externally visible, which makes filter indicator usage even more vital. Overlooking this simple step can quickly compound into prolonged exposure that traditional symptoms won’t reveal until much later.

By educating users on their pad’s wear and tear, filter indicators empower proactive maintenance. Many industries already require routine respirator inspection and replacement schedules, but with a filter indicator built-in to modern systems such as FlowCore, safety becomes more visual, intuitive, and responsive. From tradespeople to healthcare professionals, knowing when to swap filters is an indispensable skill that ensures compliance with regulations and promotes personal well-being.

Visual Signs to Watch For

From Discolouration to Wear Marks

One of the first cues your FlowCore pad is ready for replacement is visual degradation. Common signs include discolouration, especially browning or greying of the surface material. These changes often indicate particulate build-up or chemical reactions with pollutants. Over time, filters naturally absorb airborne debris, which clogs the fibres and renders the pad less permeable and effective.

Another visual clue is fraying or tearing, especially near the pad’s edges. Even if airflow feels normal, physical damage compromises the filter’s integrity. If the frame or locking edge is cracked, this could also indicate fatigue from exposure to heat, pressure, or prolonged moisture. Additionally, patches or spots that appear damp can signal condensation build-up, reducing uniform airflow and filtration properties.

Keep in mind that while visual inspection is a useful first step, it shouldn’t serve as your sole diagnostic method. A functional filter indicator complements surface-level cues, offering deeper insight into performance limitations not always visible to the naked eye.

Understanding FlowCore’s Built-in Pad Indicators

Labelled Zones and Fading Thresholds

FlowCore respiratory systems feature embedded filter indicators that rely on dye-based technology to provide a clear indication of pad saturation. These indicators typically use a colour bar or reactive strip positioned on or near the filter. As airborne contaminants pass through the pad, the chemical load slowly triggers a visible shift in the indicator’s hue—from vibrant or dark tones to lighter, faded variants.

Each FlowCore pad comes with a clearly marked zone where the indicator is housed. Initially, this zone displays a high-contrast colour—often a deep blue or red. As the internal filter media reaches its absorptive limit, the hue becomes paler or sometimes entirely disappears. This fading effect acts as a binary warning: replace or continue using cautiously.

Critical to this system is correct interpretation. Many FlowCore replacement guides include a visual chart comparing new vs expired pad indicators. Refer to your unit’s manual to get acquainted with these references. Failing to monitor the indicator accurately risks using an expired pad that appears outwardly acceptable but is functionally inert.

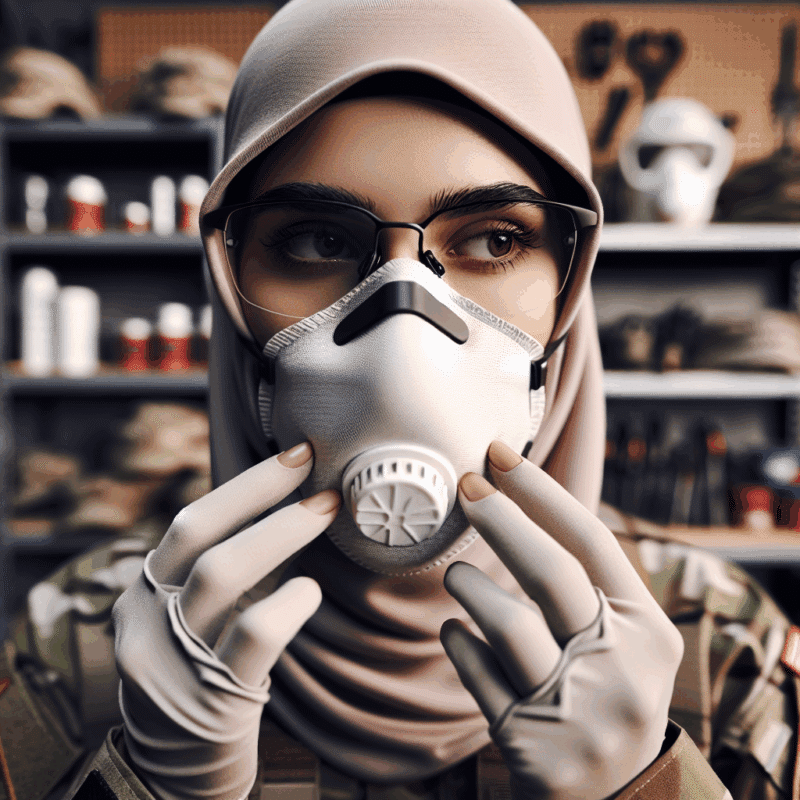

Breathing Resistance: A Tactile Warning

When Inhaling Feels Harder Than Usual

Increased breathing resistance may be the most intuitive symptom of a filter nearing the end of its usable life. A sudden change in inhalation effort is often due to accumulated particulates restricting airflow. If you’ve worn a FlowCore respirator consistently over a stretch and begin to notice heavier breathing, that’s a tactile sign your pad may be due for replacement—even if the filter indicator has not fully faded.

While FlowCore filter indicators provide the visual cue, breathing resistance acts as a behavioural nudge. It prompts users to verify the indicator and review operational hours. Don’t dismiss this change—even subtle resistance can add physical strain over time, especially during prolonged use in strenuous environments. For professionals working in welding, sanding, or laboratory-spill contexts, efficient airflow is not just comfort but a necessity for concentration and reaction time.

To assess breathing resistance accurately, compare your current experience with how the device felt post-installation. Keep a personal log if necessary. Though subjective, this method adds another layer of user-driven safety awareness alongside the visual indicator system.

How Long Do FlowCore Pads Typically Last?

Lifespan Ranges by Use Type

The average FlowCore pad lasts between 20 and 40 operational hours, but several factors can shorten or extend this range. Usage environment tops the list. For instance, working in dusty construction zones or laboratories with active particle emissions will wear filters faster than working in a controlled cleanroom. Consistent exposure to vapours, aerosols, or heavy particulates accelerates saturation, often pushing replacement needs well before visual indicators degrade.

FlowCore recommends monitoring both user experience and filter indicator changes rather than relying solely on calendar-based replacement. However, as a rule of thumb, light-use environments—such as indoor maintenance or inspection tasks—often allow filters to last beyond 30 hours. Conversely, high-load use cases like metal cutting, insulation work, or chemical processing might require pad changes closer to or below the 20-hour threshold.

Seasonal humidity, temperature swings, and storage conditions post-use can also affect pad longevity. FlowCore offers digital tracking apps to pair with certain models, which can alert you to usage thresholds elapsed. Take advantage of this technology if available to personalise your replacement schedule.

Safe Practices: When In Doubt, Change the Pad

Never Compromise on Safety

Erring on the side of caution is always the right approach when dealing with respiratory protection. If you’re unsure whether a filter pad is still effective, treat it as expired—especially if the filter indicator is close to its endpoint. It’s rarely worth the risk to extend usage for convenience or cost savings. Safety begins with proactive decision-making, a point made repeatedly in guidance from regulatory bodies like the HSE and OSHA.

As material degrades, the ability to trap smaller particulates diminishes. Damaged or depleted filters don’t keep contaminants out—they let them straight in. The margin for error is slim, and those marginal lapses could turn to long-term medical conditions. For optimal protection, check your FlowCore indicator at the beginning and end of each use cycle. Include this step in your PPE checklist.

Remember: compromised filtration undermines all other protective measures in your kit. Gloves, visors, or full-body suits are ineffective if you’re unknowingly inhaling airborne threats.

DIY or Pro Use: Replacement Schedules Differ

Customising Pad Checks Based on Work Intensity

Your usage pattern should directly impact how often you inspect and replace your filter pad. DIY users, for instance, may only operate their FlowCore respirator sporadically—during weekend projects or single-day tasks. In such cases, the filter indicator becomes especially useful as residual filtration power is lost slowly over time, not usage hours. Check it before each new project, regardless of how little it was used before.

Professionals working 8-hour shifts in high-particulate environments must often replace pads almost daily. Scheduling automatic filter checks during mid-shift breaks or before post-lunch restarts is a good practice. In industrial sites, some teams operate multiple FlowCore units in rotation to ensure clean filters are always available. These methods can drastically improve efficiency and reduce overall exposure risk.

Tailor your approach based on PPE audit reports and historical data. Companies are encouraged to maintain logs correlating filter changes with observed air quality issues. This feeds back into process improvement and keeps workers protected comprehensively.

Filter Storage & Handling

Make Pads Last Longer

Proper storage extends the effective life of FlowCore pads significantly. Once removed, pads should be stored in airtight containers free from moisture, direct sunlight, and chemical interference. Any exposure to ambient air—even if unused—can begin the slow saturation process that ultimately compromises the unit.

When reusing pads for intermittent tasks, log each session’s cumulative duration to prevent overextending lifespan. Misjudgement here means relying on a pad that has technically expired. FlowCore recommends dedicated storage racks for onsite kits and vacuum-sealed bags for field portables. The less exposure filters have between uses, the longer and more effectively they’ll perform.

Lastly, avoid handling the contact surface directly. Oil and residue from your fingers may damage or accelerate the degradation of the medium, particularly on higher-sensitivity bio-hazard models. Use gloves if necessary during installation and removal.

A filter indicator is not a suggestion—it’s your first line of defence against invisible harm.

Resources & Replacements

Where to Get Official Torxup Filters

Always purchase genuine Torxup-branded replacement pads for your FlowCore system. Third-party or counterfeit alternatives may not be compatible and risk disrupting the sensitive balance between airflow and filter density. Official pads are quality-tested and synchronised with FlowCore’s indicator strip system.

You can procure replacements through authorised distributors and licensed PPE vendors. Additionally, the Learn more about Dust Mask Maintenance & Respirator Care section of our website helps identify current filter models and their specific pad indicators. Use our lookup tool for immediate compatibility checks.

For more information on certified safety practices and equipment standards, refer to Filter pads and their roles explained. Regularly review your workspace guidelines to ensure your supplies meet your industry’s updated requirements.

Wrap-Up: Your Filter Indicator Checklist

Staying on top of your filter indicator is central to maintaining effective respiratory protection. Don’t wait for obvious wear or discomfort—always consult the filter indicator as your real-time guidance system. When visual signs align with tactile changes like resistance or odour, take swift action. And remember: replacement frequency isn’t fixed; it’s fluid, based on your environment and personal exposure levels.

Great guide on filter-indicators-when-flowcore-pads-need-replacing-guide – Community Feedback

How do I know when my FlowCore pads need replacing?

Physical signs include higher breathing resistance, visible discolouration, or marked indicators on the pad itself. Replace if in doubt or after heavy use.

What happens if I don’t replace my filter pads in time?

Continued use can reduce filtration efficiency, risk exposure to harmful particles, and shorten respirator lifespan. Timely replacement is critical for safety.

Are there any visual indicators on FlowCore pads?

Yes, FlowCore pads feature clear visual changes such as darkening, wear marks, or labelled usage indicators to signal when replacement is due.