Filter Indicators: Visual Signs FlowCore Pads Need Replacing

In This Article

- Always monitor for filter indicator signs like discolouration and breathing resistance.

- Replace FlowCore pads every 20–60 hours depending on usage environment.

- Follow safe disposal procedures to prevent contamination.

- Fraying, rigidness, or pattern-fading are not to be ignored—replace immediately.

- Scheduled inspections prolong equipment life and reduce health risks.

Understanding Dust Mask Filter Indicator Signs

Why indicators matter

Filter indicator signs are essential visual or performance cues that indicate when a filter pad, such as those manufactured by FlowCore, needs to be replaced. These warning signs exist to protect users from respiratory risks associated with continued use of a degraded filter. Ignoring such indicators can lead to diminished airflow, increased particle permeation, and potential health hazards in both industrial and domestic environments. Recognising filter indicator signs empowers users to make proactive decisions, safeguarding not only their own health but also maintaining optimal equipment performance. Whether it’s a change in colour, texture, or airflow resistance, these signals act as the first line of defence in filtration maintenance.

What Visual Signs Mean Your FlowCore Filter Pad Needs Replacing

Key physical and performance warnings

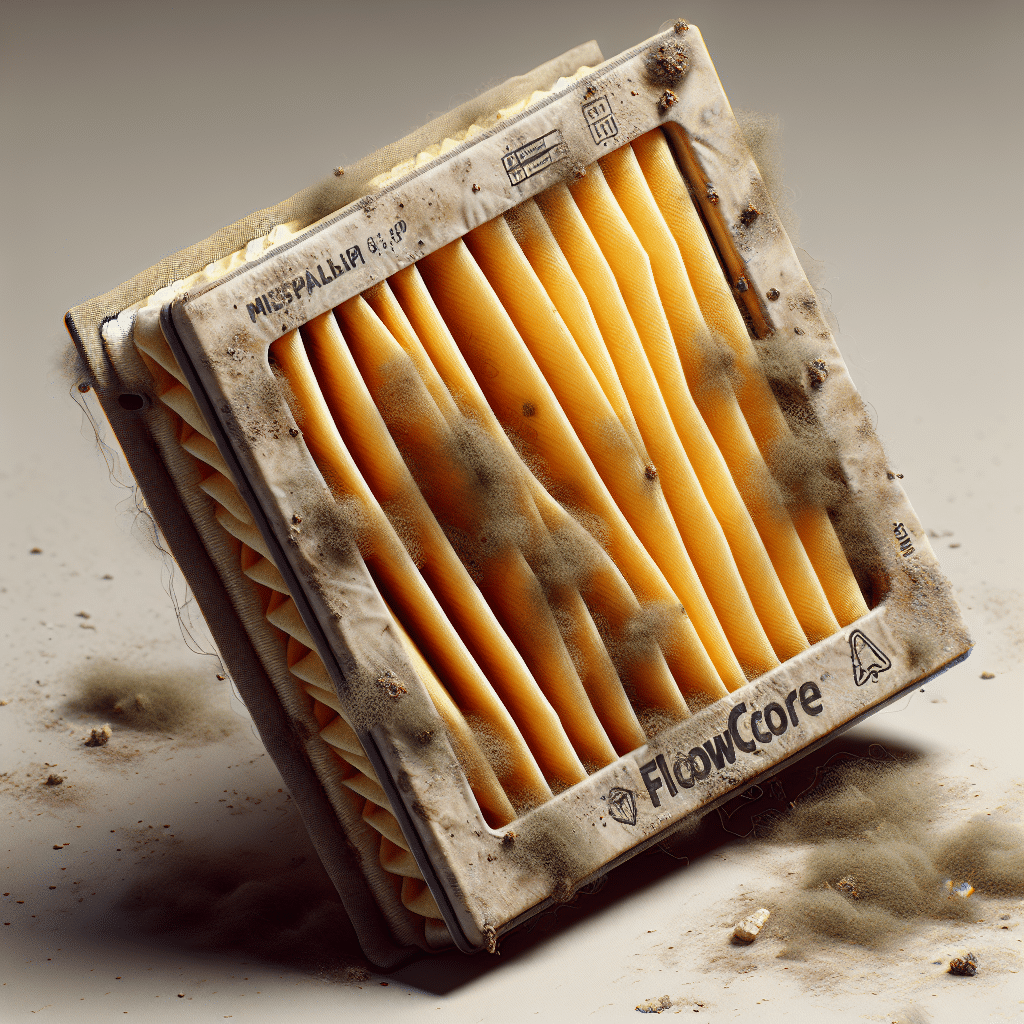

FlowCore’s filter pads are designed with intuitive physical signs to alert users when a change is necessary. One of the most common filter indicator signs is a visible darkening of the material, suggesting saturation with particulate matter. Other signs include fraying at the edges, rigid patches, or a misshaped pad contour that may indicate internal decomposition.

Functionally, an increase in breathing resistance is often one of the earliest filter indicator signs. If the user experiences difficulty inhaling or detects contaminants in supposedly clean air, filter performance has likely degraded. Some FlowCore models include pattern-fade indicators printed directly on the filter surface. When these patterns begin to disappear or change colour, it usually signifies that the filter’s efficiency is compromised and replacement is necessary.

“When the pattern fades or darkens significantly, airflow is already half as effective as it was with a fresh filter.” – FlowCore Technical Team

Common Wear and Tear on Filter Pads

From dust buildup to edge fray

Wear and tear on FlowCore filter pads typically accumulates due to environmental exposure and frequency of use. Dust buildup is often the most obvious form, forming a greyish or brown coating over time. Though not always uniform, this particulate accumulation typically appears thickest along the airflow pathway.

Edge fray is another indicator, resulting from repeated removal and reinstallation. This can lead to reduced edge sealing, allowing contaminants to bypass the main filtration zone. In some instances, users may notice that the pad has become stiff or warped, which is typically an indicator of prolonged exposure to moisture or high temperatures. Other indicative damage includes compressions on the pad surface, suggestive of internal blockage or compromised filter fibre structure.

How Often Should You Check Your FlowCore Pads?

Inspection frequency and handling tips

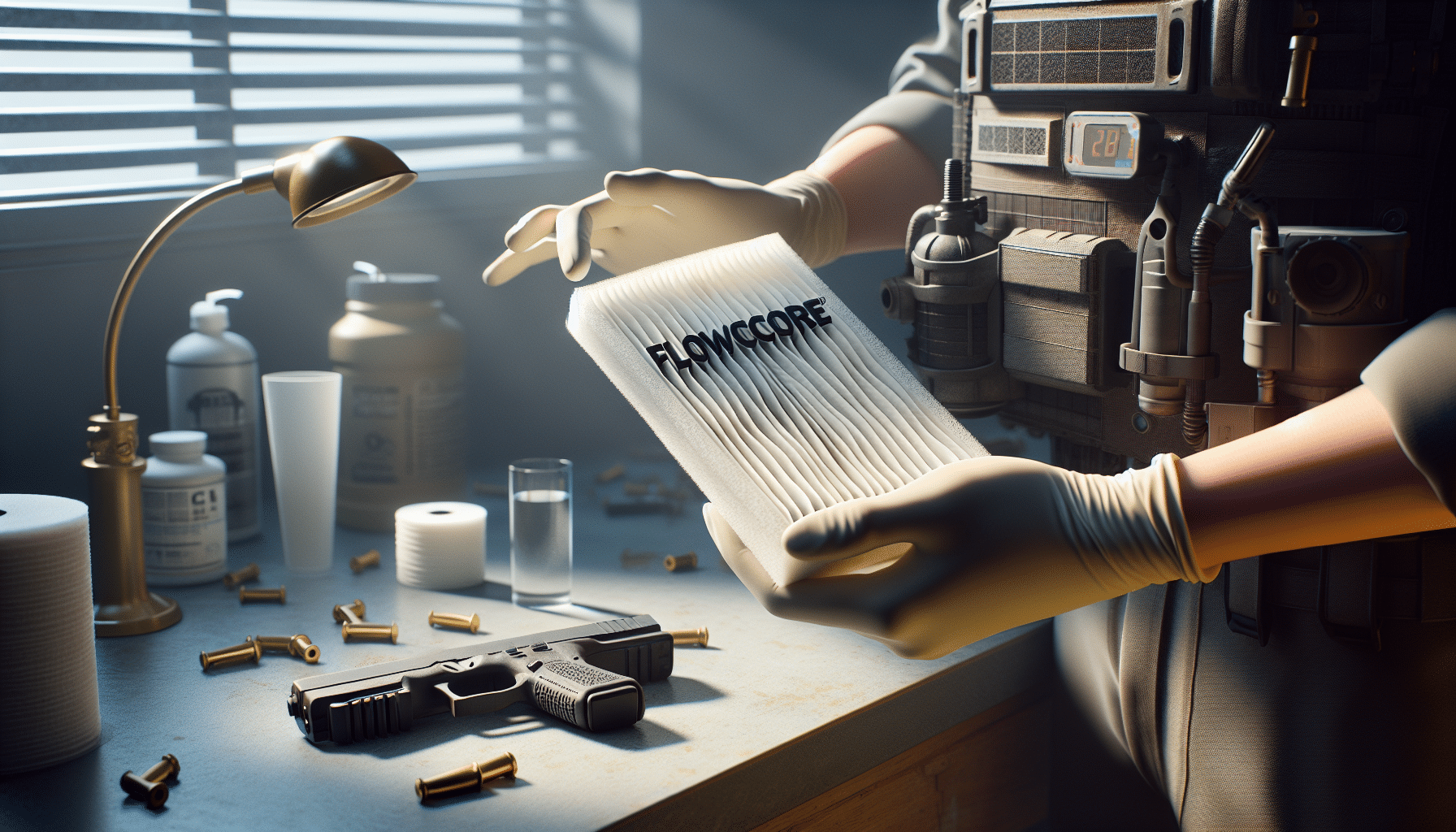

FlowCore recommends visual and functional inspections of filter pads at least once every fortnight for typical environments. In high-dust or pollutant-heavy workplaces, weekly checks are advised. Regular monitoring helps in catching early filter indicator signs such as discolouration, changes in odour, or airflow restriction. During inspection, users should wear protective gloves and handle the pad from the edge to avoid contaminating its surface or damaging the structure.

It’s best to examine the filter under good lighting, checking for tears, brittleness, or changes in filter density. Trust your senses—if it smells off or feels unusually dense, it may be time to replace it. Creating a calendar reminder for routine pad inspections promotes safe usage practices and simplifies compliance with occupational health standards. For more guidance on preventative maintenance, consult Learn more about Dust Mask & Respirator Maintenance and Filter Replacement.

Consequences of Overusing Worn Filters

Why timely replacement is critical

Neglecting filter indicator signs and continuing to use an over-worn FlowCore pad can pose serious health risks and impact work performance. As a filter degrades, its ability to trap particulates diminishes drastically, allowing harmful matter to enter the respiratory system. For workers in high-exposure environments, inhaling unfiltered air could lead to chronic respiratory issues, allergies, and fatigue.

The dangers aren’t restricted to health alone. Equipment relying on integrated air systems may become clogged or inefficient, leading to higher energy consumption and potential malfunction. Additionally, worn pads often contribute to increased operational noise due to airflow constriction. Regulatory bodies such as the UK’s Health and Safety Executive (HSE) set standards for filter maintenance and replacement. Ignoring these filter indicator signs could lead to compliance failures and liability issues. For further legal obligations and standards, review technical background on filtration indicators.

Manufacturer Guidance for Pad Replacement

Recommendations by FlowCore

According to official FlowCore documentation, replacement of filter pads should be conducted after 40-60 hours of use in clean environments and as early as 20 hours in polluted zones. However, condition-based triggers such as visible darkening, loss of airflow, or the appearance of filter indicator signs should override any fixed schedule.

FlowCore supplies a guideline sheet with every product shipment, detailing how to identify warning signs and how to conduct replacement safely. Use only FlowCore-certified replacement pads to ensure performance compliance and safety assurance. Note that warranty coverage may be voided if third-party components are used or reconditioning methods are employed without authorisation. For full manuals and support directories, explore Read a related article.

Safe Disposal and Replacement Practices

Do’s and don’ts when replacing pads

Replacing a filter properly begins with turning off any active air supply connected to the unit. Once removed, the used FlowCore pad should be placed in a sealed bag to avoid ambient contamination. Users must avoid touching the central filtration area with bare hands to prevent bacterial transfer and preserve hygiene integrity.

Never flush used pads down standard refuse systems. Follow local regulations for industrial waste disposal or consult FlowCore for certified disposal sites. Do not attempt to clean and reuse a disposable pad. Even if the surface appears intact, internal fibre damage can’t be repaired and reuse may compromise filtration efficiency. For more detailed handling techniques, consult advanced automation tips for compliance.

Maximising the Lifespan of FlowCore Pads

Helpful maintenance habits

While filter pads are ultimately disposable, there are ample practices that can extend usable life. Store unused pads in sealed, dry environments away from chemicals or moisture. During usage, ensure filters are not exposed to vapour, oils, or chemicals that could prematurely degrade the media.

Educating team members on recognising filter indicator signs allows for collaborative maintenance routines, reducing user error and prolonging operational efficiency. Additionally, always ensure pads are seated correctly during installation. Misalignments accelerate fraying and reduce contact seal quality. Smart labelling of pad installation dates can help track usage cycles and streamline replacement intervals throughout your workplace.

Case Study: Filter Lifespan in Real-World Use

What our users report

In a survey conducted across three industrial sites in Birmingham utilising FlowCore filter pads, average replacement frequency aligned closely with visible indicator signs. 78% of participants reported noticing discolouration before performance noticeably declined. One logistics facility successfully implemented a barcode-check system that tracks installations and enforces renewal every 21 days. This resulted in staff experiencing fewer incidents of fatigue and reported airborne irritants dropped by 32% over one quarter.

An engineering workshop in Manchester adopted a one-week visual inspection protocol, reducing unexpected filter failures entirely. They noted that fraying edges were their primary early filter indicator sign. The study showed that workplaces that trained staff on indicator recognition enjoyed a 15% increase in overall equipment longevity and lowered downtime due to filter-related failures.

FAQs on Filter Replacement Signs

Summarised visual references

Q: What are the most common filter indicator signs?

A: Common signs include darkening of the pad, frayed edges, increased breathing resistance, and loss of printed patterns.

Q: Can I visually inspect without removing the pad?

A: In many cases, yes. However, some internal degradation may only be evident upon removal and close examination.

Q: How should pattern fade on FlowCore pads be interpreted?

A: Pattern fading usually means particulates have settled inside the pad and efficiency has dropped significantly. It’s a clear cue to replace the pad immediately.

Q: Is odour a valid indicator?

A: Yes. The presence of unusual or musty odours indicates microbial growth or chemical saturation, both requiring immediate pad replacement.

Conclusion: Stay Proactive with Your Filter Maintenance

Filter indicator signs are not just optional suggestions— they are vital tools in maintaining effective respiratory filtration and workplace compliance. Recognising and acting on early warning cues can prevent health hazards, improve workplace efficiency, and reduce costs over time. FlowCore provides well-engineered pads with intuitive signals for a reason: to protect users before danger becomes visible. By adhering to inspection routines, following manufacturer recommendations, and educating teams on filter indicator signs, organisations can safeguard both personnel and place. Taking filtration seriously now prevents serious consequences later.

Great guide on filter-indicators-flowcore-pads-replacement-signs – Community Feedback

What are the main visual signs that FlowCore pads need replacing?

Key signs include visible discolouration, clogging with dust or debris, reduced airflow, and noticeable odour. Always follow manufacturer guidelines for specific replacement intervals.

Can prolonging filter life compromise safety?

Yes, using filters beyond their optimal life can reduce protection, increase breathing resistance, and allow harmful particles through. Change pads promptly as indicated.

How often should I check FlowCore pads for replacement?

Inspect pads before each use. Look for any warning indicators or signs of damage, especially if using your mask in high-dust environments frequently.