Do Carbon Pads Stop All Fumes? ProDefend Safety Limits Explained

In This Article

- Carbon pads adsorb volatile gases, not particles—match pad type to task.

- Filter breakthrough poses hidden risks—don’t rely solely on smell.

- ProDefend masks offer integrated safety indicators and extended filter life.

- Replace filters regularly and record use time for optimal safety.

- Community knowledge can enhance DIY filter management practices.

What Are Carbon Pad Filters?

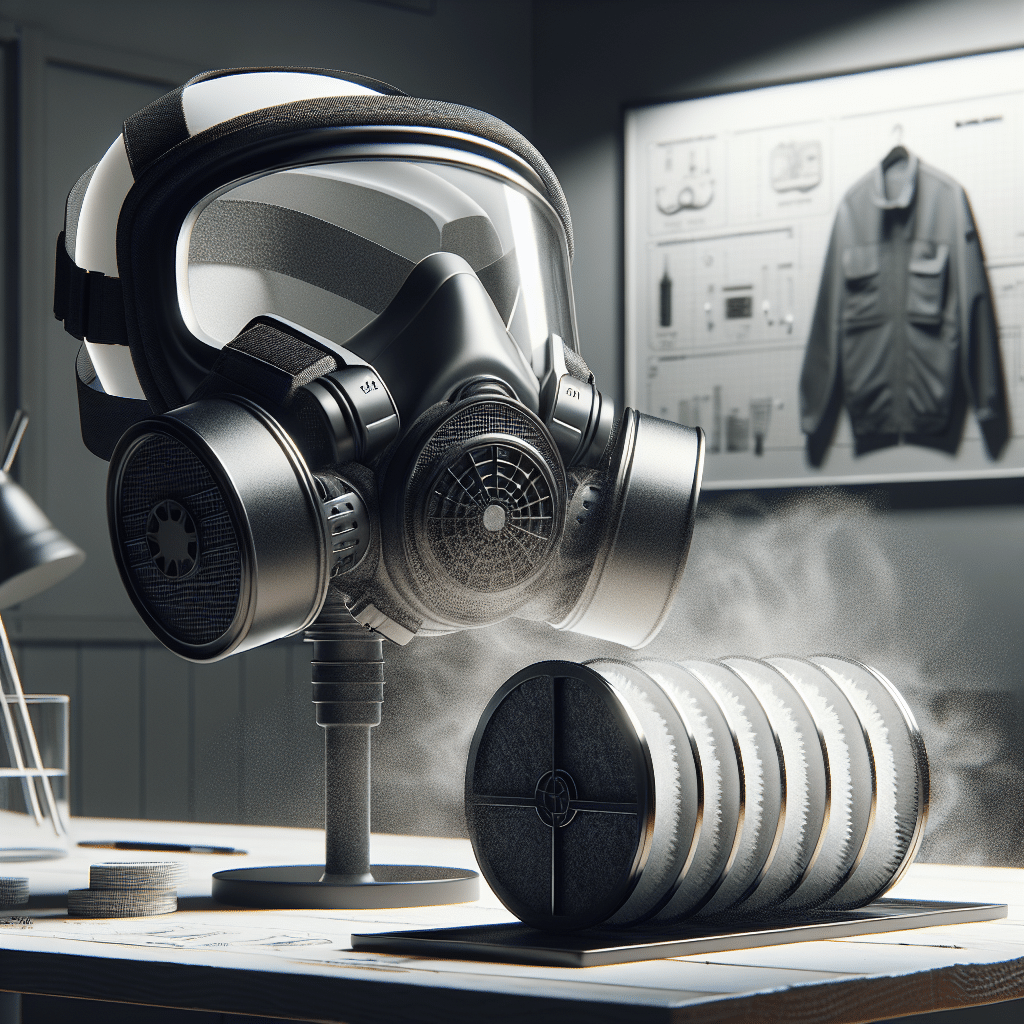

The Basics of Activated Carbon in Respirators

Carbon pads are specialised filters that use activated carbon to trap harmful gases and vapours that would otherwise pose a danger to the respiratory system. Activated carbon, also known as activated charcoal, consists of carbon that has been treated to make it extremely porous. These microscopic pores have a vast surface area, allowing them to adsorb a wide range of volatile organic compounds (VOCs), including solvents, paint fumes, and industrial chemicals.

This type of filter is widely used in industrial settings such as painting, laboratory work, and DIY environments where airborne contaminants can be present. When air passes through a carbon pad, the specific molecules stick to the surface of the carbon granules in a process called adsorption (not absorption). Unlike fibrous particulate filters that trap physical dust and particulates, carbon pads target chemical vapours and gases that cannot be caught by mechanical means alone.

Do Carbon Pads Stop All Fumes?

Understanding Absorption Limits and Filter Lifetime

Although carbon pads are effective against a wide spectrum of fumes, it is critical to understand that they do not stop all chemical vapours indefinitely. Their functionality relies on adsorption capacity, which is finite. Once the carbon is fully saturated with captured molecules, it loses its effectiveness and may even allow fumes to pass through unfiltered—a phenomenon referred to as “breakthrough.”

Breakthrough does not always mean that you will immediately notice fumes via smell. Certain chemicals do not have tell-tale odours or may only be detectable at concentrations already harmful to human health. Therefore, merely relying on odour detection can be dangerous.

“A carbon pad is only as good as its condition—odour alone is not a reliable indicator of filter capacity.”

How ProDefend Masks Signal Odour Breakthrough

ProDefend masks have integrated features that enhance user awareness of filter performance. One key innovation is their odour detection system, which helps notify wearers of odour breakthrough through noticeable sensory thresholds. These thresholds are calibrated to coincide with when the carbon pad should be changed, increasing user safety for solvents like toluene, xylene, and acetone.

Unlike traditional carbon pads that rely solely on user interpretation, ProDefend includes visual or auditory alerts on some models. These advanced cues prompt mask users to replace filters before exposure reaches unsafe levels. Understanding when your pad is nearing exhaustion allows you to avoid the pitfalls of relying on manual guesswork.

Exposure Limits and Saturation Timelines

Each carbon pad has a unique saturation timeline based on its construction, the volume of carbon it contains, and how heavily it is used. High-exposure environments, such as prolonged spray painting or solvent cleaning, can reduce the lifespan of a carbon pad from weeks to days—or even hours in extreme cases. Environmental factors such as heat and humidity also decrease adsorption capacity.

To protect users, various regulatory bodies define permissible exposure limits (PELs) for a wide array of airborne chemicals. Once the carbon pad has adsorbed compounds up to these regulatory thresholds, it can no longer protect effectively. Hence, understanding the expected chemical exposure for your task is paramount when choosing a filter.

Solvent Safety: Matching Filter Type to Task

It is imperative that users match the type of carbon pad to the specific chemicals they are expecting to encounter. Carbon filters are not universally effective against all chemical vapours; some compounds, such as ammonia or formaldehyde, require specialised impregnated carbon filters. Always consult the Safety Data Sheet (SDS) of the material you are working with to determine compatibility and required filter type.

Using the incorrect type of filter pad can lead to rapid breakthrough, hazardous exposure, or even long-term health effects. Whether you are handling oil-based paints, lacquers, or industrial solvents, the right match matters. For further guidance, see our Learn more about Respirator Performance and Filter Safety Standards on selecting carbon filter types by chemical family.

When to Replace Your Carbon Filter Pads

Timely replacement of carbon pads is a critical best practice. Waiting until fumes are noticeable can jeopardise user health. Ideally, a replacement schedule should be established based on the manufacturer’s recommended use time, the working environment, and observed odour breakthrough indicators. ProDefend pads often include colour indicators or digital sensors to support replacement awareness.

If you begin to detect even faint traces of chemical smell, it is advisable to cease work and replace the filter immediately. Mask users operating in especially volatile environments should consider rotating filters more frequently than casual users. To help track usage, maintain a written log of working hours per pad in industrial or workshop settings.

Choosing the Right Mask for Paint and Solvent Fumes

When handling solvents and paint fumes, not all masks offer the level of protection required. Many consumer-grade masks provide only particulate filtration, which does not address chemical vapours. To protect against solvents effectively, you need a full-face or half-mask respirator with fitted carbon pads.

ProDefend masks are designed to provide enhanced protection through ergonomic fit, multiple-layer filter design, and integrated detection features. DIY users often underestimate the need for professional-grade filtration, especially when working with thinners, turpentine, and other hobbyist solvents. Investing in a high-quality mask with replaceable carbon pads is a vital step for both safety and comfort.

ProDefend vs. Standard Filters: What Sets It Apart?

The distinction between ProDefend and standard filters lies in several core features. Firstly, ProDefend uses finely graded activated carbon with consistent pore distribution. This allows for more uniform gas capture and longer effective filter life. Many competitors use lower-density carbon with inconsistent granule sizes, reducing efficiency.

Secondly, ProDefend includes advanced symptoms-monitoring integrations—such as filter end-of-life indicators—and compatibility with a broader range of filter chemistries. These characteristics make ProDefend a preferred choice for professionals in painting, flooring, laboratory work and more. Comparative filter tests have shown up to 40% longer effective filtration compared to standard pads, particularly in high-fume environments. For case studies and laboratory comparisons, view our Are carbon pads truly effective for fumes.

Community Tips for DIY Mask Use

Across hobbyist and DIY communities, shared knowledge helps users maximise the efficacy of carbon pads while staying safe. Here are a few practical tips:

- Store unused carbon pads in airtight containers to prevent early exposure to ambient fumes.

- Label each pad with the date of first use to track lifespan.

- Rotate between two masks to allow one set of filters to off-gas and decompress overnight.

- Clean mask seals regularly to preserve air-tight fitting and comfort.

Forum users have shared further insights into maximising ProDefend filter efficiency, many of which are compiled in our Read a related article respirator best practice guide.

Best Practice Maintenance for Longer Filter Life

Taking care of your carbon pads through proper maintenance helps extend usable life while preserving performance. Store filters in a sealed, dry environment after use. Do not expose them to open air when not needed, as they will continue to adsorb background household chemicals and humidity even when idle.

Inspect carbon pads and respirator components for signs of wear or damage before each use. Replace the full mask unit if contaminated or compromised. Many users make the mistake of assuming filters last indefinitely when not used consistently. In reality, adsorption starts from the moment an airtight seal is broken.

Do’s and Don’ts of Carbon Pad Protection

Do:

- Check your manufacturer’s specifications for use duration and replacement frequency.

- Keep extra carbon pads on hand in high-use environments.

- Match filter type explicitly with the chemicals you handle.

Don’t:

- Use a carbon pad past noticeable odour breakthrough.

- Assume protection without a proper airtight fit.

- Discard used pads loosely—contain and dispose according to chemical waste protocols.

Following these guidelines ensures the best possible defence against fume exposure while enhancing the longevity of your equipment. For environmental disposal standards, check the Automated SEO support for compliance sites.

Conclusion: Staying Safe While Working with Solvents

[CONCLUSION_CONTENT]

Using carbon pads within your respirator setup is a fundamental safety protocol when dealing with paint, solvents, and other gaseous hazards. However, carbon filtration is not infallible. Understanding its limitations, knowing how to select suitable pads, and recognising odour breakthrough are all critical components of effective protection. ProDefend offers value and reliability with specialised enhancements that support safety and filtering accuracy at every stage. By properly maintaining your equipment and staying informed, you build a robust defence against airborne danger, ensuring your health remains uncompromised in even the most challenging environments.

Great guide on do-carbon-pads-stop-fumes-prodefend-limits-explained – Community Feedback

Do carbon pads stop all fumes?

No, carbon pads reduce but do not stop all fumes. Their effectiveness depends on the type, concentration, and saturation of contaminants. Regular filter changes are critical for ongoing protection.

How do ProDefend masks signal odour breakthrough?

ProDefend masks signal odour breakthrough if you start to smell or taste the contaminant through the mask, indicating the filter’s carbon layer is saturated and needs replacing.

What are the limits of carbon safety filters for solvents?

Each filter has exposure limits based on contaminant type and duration. For strong solvents or high concentrations, specialist filters and strict adherence to safety guidelines are necessary.