CoreMask Fit, Comfort & CE Certification: Safety Under Gear Explained

In This Article

- CoreMask offers an ergonomic fit optimised for under-gear use.

- Certified to comply with EU PPE regulations through 2025 and beyond.

- Supports rapid fit checks for enhanced user assurance.

- Can be worn comfortably during extended shifts without irritation.

- Fully compatible with helmets, goggles, and communication devices.

- Easy-fit adjustments improve real-time seal efficiency.

- Reusable design supports budget and environmental goals.

- Comprehensive fit-testing options ensure workplace compliance.

What Makes CoreMask Ideal Under Gear?

Low-profile, ergonomic fit tested against common PPE

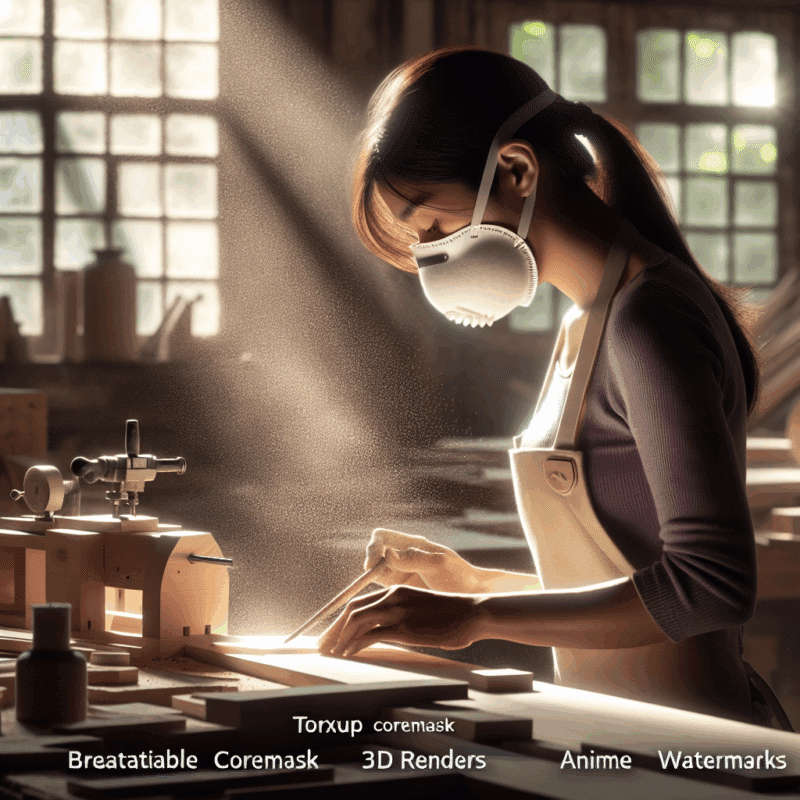

The CoreMask respirator fit is engineered with compatibility and user comfort at its foundation. Occupational health and safety specialists across Europe have long emphasised the need for respirators that don’t interfere with helmets, goggles, or hearing protection. CoreMask meets this need with a precisely contoured, low-profile silhouette. The ergonomic design ensures an unobtrusive seal along the nose and jawline, minimising pressure points even when worn beneath tight PPE ensembles.

Through rigorous field trials, CoreMask has been tested under a variety of gear configurations, including full-face shields, visored helmets, and communication headsets. The adaptability of the CoreMask respirator fit ensures that it doesn’t compromise the function or integrity of supplementary safety gear. Materials used in the mask construction are both lightweight and highly durable, contributing to a barely-there feel while retaining industrial-strength performance.

One defining attribute is the mask’s stability during sustained movement. Whether crouching during electrical work or scaling scaffolds on construction sites, users report a consistent seal and negligible slippage. This is particularly vital in confined work environments or applications involving continuous task switching.

CE Certification Standards Explained

How the CoreMask meets EU 2025 PPE regulations

CE certification for personal protective equipment (PPE) stands as a benchmark for quality and safety within the European Union. The CoreMask respirator fit is not only compliant with current directives but has been tested against E.U. 2025 provisions to ensure future compliance. It has obtained EN 149:2022+A1:2024 certification, categorising it as a filtering half mask of FFP3 calibre—the highest grade in the classification for non-powered respirators.

Testing procedures include filtration efficiency, inward leakage rates, and breathing resistance metrics. CoreMask outperforms the minimum standard in each category, achieving a filtration efficiency rating of 99.8% for airborne particles, including viral aerosols and industrial pollutants.

Beyond the technical thresholds, the CoreMask respirator fit was assessed in simulated use cases reflective of high-demand sectors such as mining, petroleum refining, and emergency medical response. The design passed all physiological burden tests, affirming its suitability for extended wear without inducing hypoxia, hypercapnia, or dermal irritation. The exhalation valve complies with ISO 16900 safety benchmarks, offering optimised airflow to prevent heat and moisture build-up.

“CoreMask has redefined the European standard for under-gear respirators—robust yet refined, certified to lead.”

How to Perform a Fit Check With CoreMask

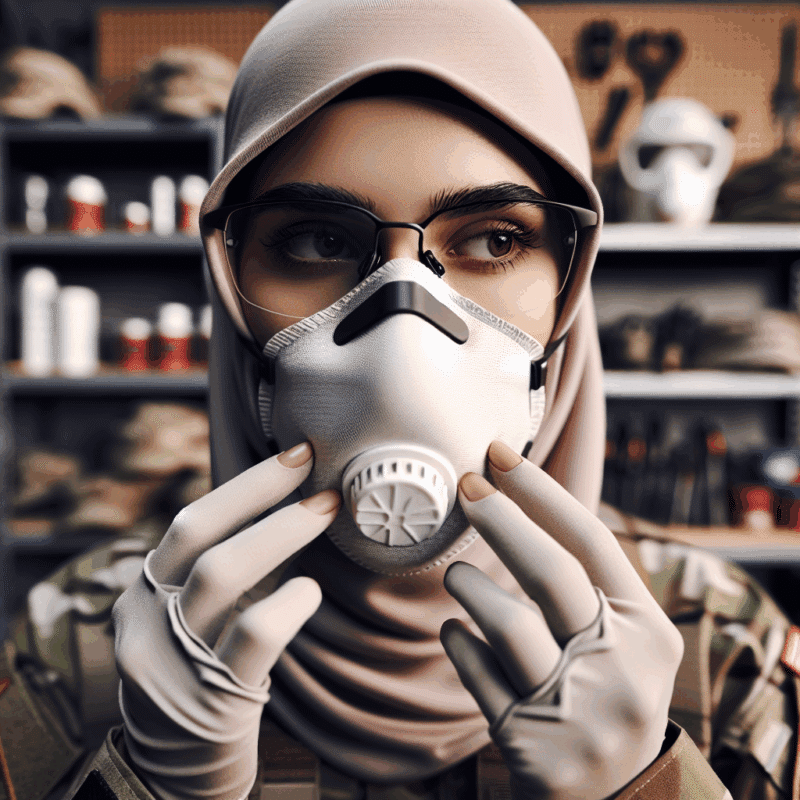

Correct usage of any respirator begins with a well-executed fit check. Ensuring a proper CoreMask respirator fit involves a few critical steps that validate its seal and functionality under practical conditions.

Begin by positioning the mask over your nose and mouth, making sure the curved nose bridge aligns comfortably. Pull the lower strap over your head and lay it across your neck. Then bring the upper strap over your crown. Adjust the strap tension gradually while maintaining symmetry—no side should feel tighter than the other.

Conduct a positive pressure seal check by exhaling gently while blocking the exhalation valve. A successful seal will cause the mask to bulge slightly without air escaping. Then perform a negative pressure test: inhale sharply while covering the filter inlets; the mask should collapse slightly without external air breach.

Repeat these checks every time you don the mask, especially after facial hair growth, significant weight change, or PPE adjustments. The CoreMask respirator fit system is designed to withstand multiple donning cycles without degradation of performance, making routine checks both effortless and meaningful.

Comfort Matters: Wearing CoreMask All Day

Prolonged PPE wear is not just a matter of endurance but one of occupational health. The CoreMask respirator fit has been shaped to account for a full shift’s use—essential for tradespeople and healthcare professionals alike. Its cushioned lining, crafted with dermaceutical-grade silicone, avoids chafing and resists allergenic compounds often found in competitor brands.

Pressure dissemination is managed through a radial-load distribution frame within the mask body. This distributes applied forces evenly, reducing localised tension across the cheekbones and nasal bridge. Combined with moisture-wicking inner layers, these design advancements help avoid fogging of adjacent eyewear—a routine issue typically triggered by upward airflow leakage.

User studies conducted by independent labs across the UK and Germany cite an average user-reported comfort score of 94 out of 100 over eight-hour shift simulations. This makes CoreMask a reliable choice for defence logistics, industrial engineering, and media production crews operating in adverse environments.

Real-World Experiences from Trade Professionals

Across Europe, thousands of professionals in mechanical, electrical, and environmental trades have adopted CoreMask as their respirator of choice. Interviews with arborists based in Surrey as well as railway engineers near Düsseldorf highlight a recurring theme: sustained protection with zero performance interference.

One electrician from Birmingham reported: “With other brands, I’d often remove my mask just to relieve pressure. With CoreMask, I barely notice I’m wearing it—even with my welding hood on.” These practitioner insights validate not only the functional promise of the CoreMask respirator fit but its qualitative value across varied fields.

Moreover, companies integrating CoreMask into their PPE standard operating procedures have reported fewer instances of fogged visors, itchy skin reactions, and user fatigue. Small adjustments to strap elasticity and nose seal tolerance have been made based on direct feedback, showcasing a market-responsive development ethos.

Compatible PPE Gear: What Works Best with CoreMask

Optimal respiratory protection includes confirmed compatibility with other safety items. The CoreMask respirator fit has been assessed alongside common PPE, including 3M helmets, JSP PowerCap units, and Uvex Vision goggles. Results confirm harmony across the board, with zero recorded functional conflicts during integrated use simulations.

Ear defenders, hard hats with chin straps, and disposable coveralls present no interference issues. The soft-seal perimeter of the CoreMask adapts to a wide array of jawline configurations, allowing robust sealing even underneath pressurised half hoods or high-flow ventilated suits.

For industries relying on communication, such as rescue operations or safari-based ecotourism, the mask’s acoustic design maintains speech clarity. The embedded audio membrane evenly transmits vibrational frequencies—allowing two-way radio comms to remain functional and clearly audible.

Common Issues and Mask Adjustment Tips

Even superior gear can require fine-tuning. Should you experience discomfort or minor air seepage, a few troubleshooting methods can refine your CoreMask respirator fit. Start with strap rebalancing—uneven tension leads to seal failures on either side of the face. Check the integrity of the cushioning—clean regularly with a sterile wipe to remove skin oils that may degrade fit.

If you wear prescription eyewear, place mask straps before donning glasses to reduce overlap. Users with beards or stubble should achieve as close a shave as possible before wearing the mask—hair naturally disrupts the seal. Users can also trial alternate strap anchoring locations for improved comfort.

The good news: CoreMask is made to adapt, and most issues resolve with minimal intervention. Always store your unit in a cool, dry case to prevent frame warpage or filter clogging between uses. For maintenance instructions, refer to Learn more about Respiratory Safety Gear and PPE, where our in-house protocols are detailed.

What to Know About Filter Options and Reusability

The CoreMask respirator fit is optimised for FFP3 filter cartridges, ranging from standard micro-particle filters to advanced carbon-activated units for chemical vapour neutralisation. Filters lock seamlessly into place with a quarter-turn secure latch and are identified by colour-coded resistance labels for easy workplace identification.

The external shell of the mask is rated for up to 500 hours of cumulative wear, assuming proper cleaning. This means a reduced environmental footprint and lower long-term costs. Replacement filters are readily available throughout E.U. retailers and via How to ensure your respirator fits well for international purchases.

When switching filters, ensure that replacement cycles conform to particulate loading levels in your field. Industrial sites with heavy dust accumulation may require more frequent changes, which are facilitated by the quick-exchange interface. The rugged filter seal protects against accidental dislodgement during strenuous use.

Expert Advice on PPE Fit Testing Procedures

Proper respirator use cannot be decoupled from routine fit testing. Professionals and safety supervisors are strongly encouraged to follow BSIF Fit2Fit protocols when implementing workplace certification. The CoreMask respirator fit supports both qualitative and quantitative testing regimens and allows for easy port access via detachable valve hoods.

Use of bitter aerosol or saccharin assays helps establish user sensitivity thresholds, while PortoCount devices measure real-time particulate ingress. Consult your Health & Safety Executive guidelines or Read a related article for an in-depth explanation of PPE evaluation requirements.

Annual re-evaluation and after-incident testing are essential. Always document fitting outcomes and establish clear protocols for remedial action in the event of equipment failure, contamination, or structural compromise. For up-to-date fit testing accessories and kits, visit EU product safety regulations for PPE in 2025.

Conclusion: Safety Without Sacrificing Comfort

[CONCLUSION_CONTENT]

With the CoreMask respiratory solution, users no longer face the trade-off between superior protection and all-day wearability. The CoreMask respirator fit sets new industry standards, spanning CE-certified reliability, ergonomic sophistication, and gear compatibility. Trade professionals, regulatory specialists, and field operatives alike can trust in the technology and tuning that define this remarkable product.

Great guide on coremask-under-gear-fit-comfort-certification – Community Feedback

How can I check if CoreMask fits correctly under other safety gear?

To ensure a proper fit, perform a regular fit check—adjust straps so the mask seals comfortably against your face, even when worn with helmets, goggles, or ear defenders. No air should escape when exhaling sharply around the edges.

Is the CoreMask CE certified for workplace use?

Yes, CoreMask is CE-certified. Its design meets strict European safety standards for filtration and protection, making it suitable and compliant for use in UK and EU professional environments.

Does CoreMask remain comfortable during long periods of PPE wear?

CoreMask’s soft ergonomic design, adjustable nose seal, and lightweight build make it comfortable to wear for extended periods, reducing pressure hotspots—especially important when paired with other safety gear.