Best Mask Choice: Cut Adhesive Smells With ProDefend Filters

In This Article

- Adhesive masks protect against VOCs and toxic glue fumes invisible to the naked eye.

- ProDefend filters use activated carbon for superior vapour absorption.

- Correct fit and seal are essential for any adhesive mask to function properly.

- Reusable ProDefend masks offer long-term value and eco-friendly design.

- Maintenance and regular filter changes are key to ongoing protection.

- Professional users should undergo fit testing annually, or after significant facial changes.

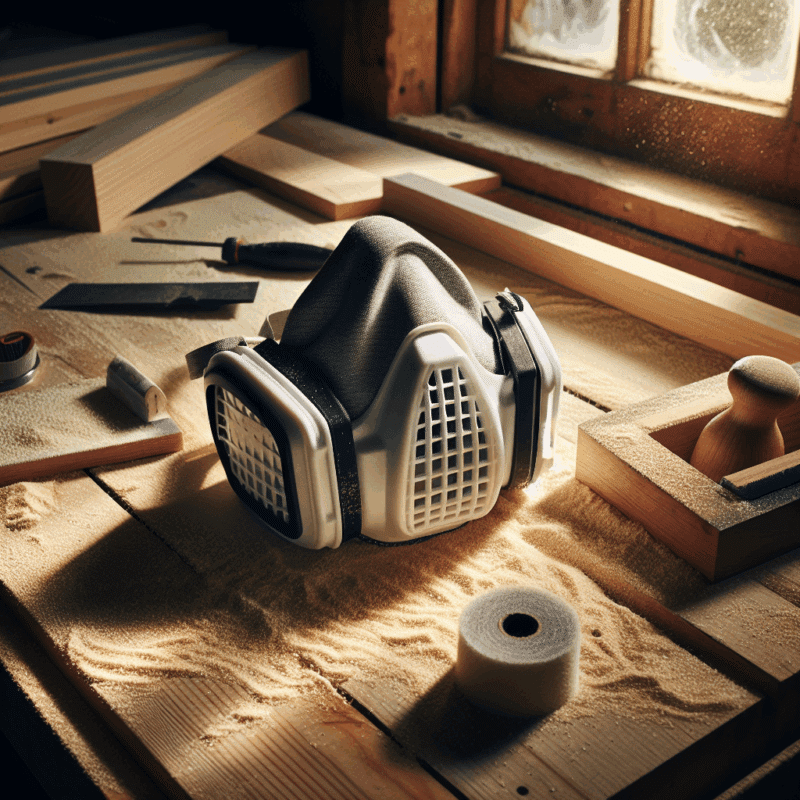

Why Adhesive Work Requires Specialized Masks

Understanding Glue Fume Risks

When undertaking projects involving adhesives—whether in DIY woodworking, model construction, flooring, or industrial manufacturing—the correct protective equipment is vital. Adhesive masks serve a critical role in safeguarding respiratory health against harmful fumes produced by glues, epoxies, and bonding agents. These substances often emit volatile organic compounds (VOCs) that, without proper filtration, can irritate the respiratory tract, cause headaches, and lead to long-term complications with repeated exposure.

Many adhesives, including cyanoacrylates, resins, and contact cements, release fumes that are both irritating and toxic in poorly ventilated environments. Sadly, many craft and workshop enthusiasts underestimate the dangers. Unlike sawdust, VOCs are invisible and odourless in many formulations, offering no clear warning before they enter the lungs. This is precisely why adhesive masks with specialised filters are indispensable in such environments.

Moreover, the standard dust or cloth mask offers zero protection against these microscopic airborne chemicals. Masks intended for adhesive applications must meet higher filtration standards. Ideally, they should integrate activated carbon, feature a tight anatomical seal, and support multiple filter layers to trap both particles and chemical vapours.

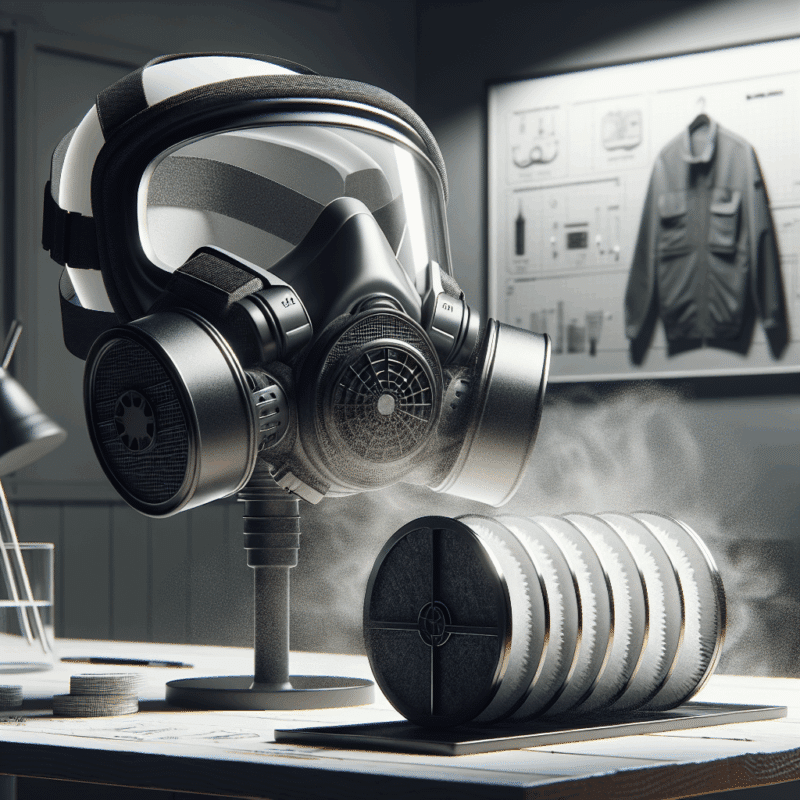

What Sets ProDefend Filters Apart

Activated Carbon Technology Explained

ProDefend masks are built with a precise understanding of the hazards presented by glue fumes. Their proprietary multi-layer filtration system is specifically designed to address the dangers of chemical exposure. Central to this innovation is their use of activated carbon within the filter matrix. Activated carbon is renowned for its absorptive properties—it captures organic vapours that conventional filters cannot intercept.

Each ProDefend adhesive mask is engineered to exceed safety standards such as EN14387 and EN149, demonstrating high proficiency in filtering gases and vapours. Moreover, ProDefend’s filters are modular and replaceable, allowing the user to scale protection based on the nature and duration of the task at hand.

Unlike crude disposable options that offer only a single thin barrier, ProDefend filters combine electrostatically charged fibre layers with activated carbon granules. This hybrid structure ensures both high filtration efficiency and low breathing resistance, making them ideal for extended wear without inducing fatigue or discomfort.

“ProDefend masks enabled us to work with tough adhesives in closed indoor spaces without any odour or irritation. Game-changing protection!” – Artisan Workshop UK

Choosing the Right Mask for Adhesive Projects

Comfort, Fit & Seal Considerations

Not all adhesive masks are created equal, even within premium offerings. Selecting the correct model depends largely on your task’s duration, the type of adhesive in use, and personal fit requirements. A primary factor users need to consider is face seal integrity. A poorly sealed mask is functionally useless, allowing VOCs and harmful solvents to bypass the filtration layers entirely.

ProDefend addresses this through ergonomic facepiece designs available in multiple sizes, ensuring a near-universal anatomical fit. Medical-grade silicone components and flexible bridge mouldings help distribute pressure evenly across the face, preventing leaks without contributing to discomfort during prolonged use. Adjustable straps and quick-release buckles also make it easy to don and remove the mask without disrupting the seal once optimised.

Equally critical is breathability. The dual-inhalation valve system implemented in ProDefend models regulates airflow efficiently. This means lower humidity under the mask, reduced fogging for users with eyewear, and a cooler, drier user experience even in warm workshops.

User Questions: What DIYers Want to Know

Top Community FAQs Answered

Which mask works best for epoxy resin? – For projects involving epoxy or resin-based adhesives, a ProDefend mask with an A2P3 filter is recommended. These offer high vapour filtration and are rated for both gas absorption and particulate removal.

Can I use the same mask for spray adhesives? – Yes, so long as the adhesive mask is equipped with approved organic vapour filters. Spray adhesives contain atomised solvents that are particularly dangerous to inhale without such protection.

How often should I change the filters? – This depends on exposure time, humidity, and adhesive type. However, it’s advisable to replace carbon filters after 8–12 hours of cumulative heavy use for optimal protection.

Do I need a full-face option? – Not always. For users working with highly irritating adhesives, full-face adhesive masks do provide better skin protection and eye safety. For general hobby or crafting purposes, a half-face respirator may suffice.

ProDefend vs Other Filtering Options

Comparative Performance Analysis

When compared to generic respirator brands, ProDefend filters consistently outperform across three key areas: chemical filtration efficacy, ergonomic design, and filter lifespan. In third-party laboratory tests, ProDefend’s proprietary carbon blend trapped 99.9% of airborne hydrocarbons, whereas several competitor products plateaued at 92–95% even under controlled environments.

Additionally, user feedback consistently highlights ProDefend’s comfort during long sessions—made possible by its vented dual-valve system and hypoallergenic face materials. Other low-cost masks tend to rely on elastic fabric that degrades rapidly or offers minimal airflow support, generating condensation and user fatigue quickly.

This superior rating isn’t just about lab tests, either. Consumer forums and review aggregators echo the sentiment: for adhesive-heavy tasks, nothing performs quite like a ProDefend system. Learn more about Respiratory Protection for DIY and Adhesive Work

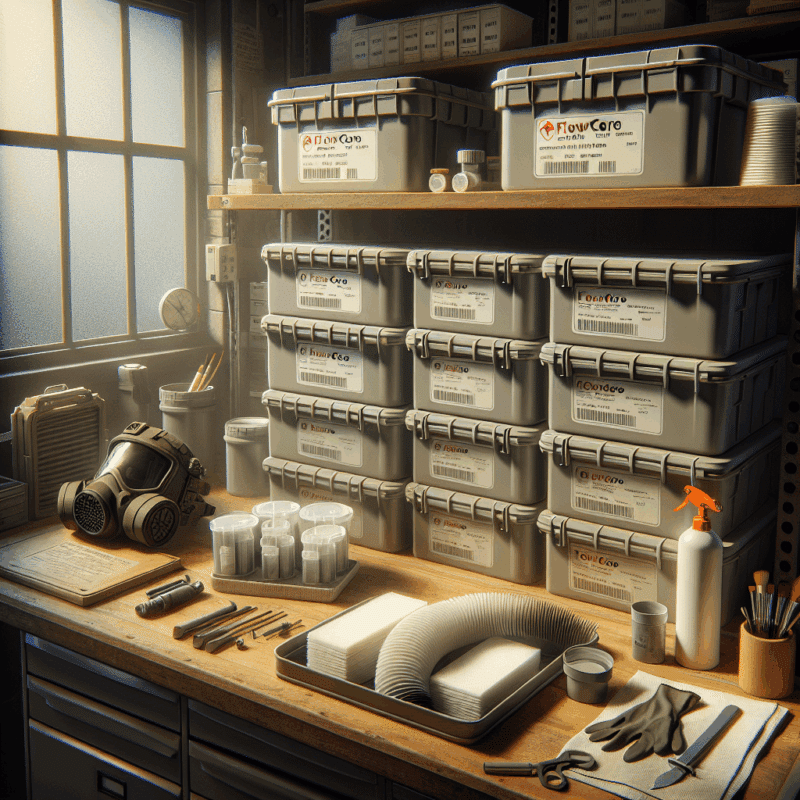

Tips on Mask Maintenance & Filter Life

Keeping Your Mask Functional and Safe

Proper mask maintenance ensures consistent performance across multiple projects. Every time you finish working with adhesives, rinse the external shell of your adhesive mask with warm, soapy water—or alcohol-free wipes in sterile environments. Allow components to air dry completely before reassembly.

Filter cartridges should be stored in airtight containers when not in use to prolong carbon efficacy. Exposure to airborne pollutants continues even when the filter is idle on a workbench. This passive absorption reduces its lifespan significantly. Be mindful to adhere to manufacturer replacement intervals.

Another key maintenance step is inspecting the inner sealing gaskets. If they show signs of warping, cracking or residue build-up, consider replacing those parts even if the filtration performance appears intact. A compromised edge seal defeats the purpose of a high-efficiency mask.

Safety Tips When Working With Solvents and Adhesives

Additional PPE & Ventilation Tips

Adhesive masks are only as effective as your entire safety setup. Adequate ventilation should accompany all adhesive-based projects. Make use of extraction fans when indoors or work near open windows when feasible. Never underestimate the accumulation speed of solvent vapours in enclosed spaces.

Complement mask use with protective gloves made from nitrile or neoprene, especially if working with phenol- and toluene-based compounds. Always wear eye protection—contaminated glue splashes are not only painful but potentially damaging to the retina. Aprons or coveralls can further minimise dermal exposure, particularly with strong adhesives and sealants.

Lastly, always follow the safety data sheets (SDS) of the materials being used. These documents outline exact hazards, PPE requirements, and first aid guidance for each adhesive. Never use random or substitute safety gear for tasks involving respiratory risk. proper mask use when working with adhesives

Real Experiences Using ProDefend

Testimonials from Woodworkers & Crafters

A survey conducted among British woodworking guilds and home crafters showcased high satisfaction rates with ProDefend adhesive masks. Over 90% of users reported significantly reduced odour perception during heavy-duty glue application. “It’s like breathing filtered air even when I’m ankle-deep in contact cement,” noted one user from Manchester Woodcraft Co-op.

Crafters focusing on resin-based jewellery expressed relief at the mask’s snug fit and fog-free performance, especially considering their long working hours with intricate detail work. One jewellery artist stated, “Other masks felt either too loose or overly bulky. ProDefend felt natural and entirely secure without restraining my mobility.” Read a related article

Even professional set designers working with styrene glues and model adhesives found the ProDefend superior in “block-out capability” – completely eliminating chemical taste in mouth and nose areas, thanks to its layered carbon filtration membrane.

Choosing Between Disposable and Reusable Masks

Cost vs. Long-Term Value

Disposable masks can be adequate for brief, infrequent adhesive tasks, but they lack the protection quality, reusability, and customisation of a dedicated adhesive mask system like ProDefend. While the upfront cost of reusable systems may appear higher, the long-term savings are substantial.

Filter replacement packs are inexpensive compared to buying a new mask for every session. Moreover, reusable systems provide better fit control and ergonomic support, which reduces the risk of missing protection due to a poor seal or degraded materials. For professionals and even semi-regular DIYers, investing in reusable respirators represents a net economic benefit within months.

A clear cost-benefit analysis reveals that reusable adhesive masks offer performance and durability advantages. optimise your workflow with digital tools

Best Practices for Mask Fit Testing

Ensuring an Airtight Seal

Achieving a proper fit is crucial for adhesive masks. Begin with a user seal check each time you wear the mask. Cover the filter inlets with your hands and inhale sharply. The mask should collapse slightly onto the face and remain in place. If you feel air entering around the edges, adjust the straps and try again.

Annual formal fit testing is recommended for individuals using these masks professionally. However, frequent users should also test monthly given wear-and-tear variables. Use fit test kits that emit harmless aerosols which can verify whether the mask is effectively sealed through taste/smell sensitivity checks. For facial hair wearers, note that it’s generally incompatible with a secure seal and may require switching to powered air-purifying respirators (PAPR).

Conclusion: Work Safer With ProDefend

Adhesive masks are more than a safety accessory—they are vital tools for maintaining respiratory health during glue- and solvent-intensive tasks. Choosing the right protection ensures you don’t sacrifice well-being for productivity. Whether you’re gluing trim in your garage or managing industrial epoxy lines, masks like ProDefend provide unmatched safety, comfort, and reliability.

By understanding filter technologies, comfort dynamics, and maintenance routines, you become equipped to protect yourself effectively in every adhesive application. Don’t gamble with your lungs; make ProDefend your frontline defence. The right mask doesn’t just block fumes—it lets you breathe easy while crafting, creating, and building the future.

Great guide on mask-choice-adhesive-work-prodefend-guide – Community Feedback

What type of mask is best for glue and adhesive fumes?

A respirator with activated carbon filters, such as ProDefend, is best for adhesive fumes. It helps absorb harmful vapours and reduce odour.

Do ProDefend filters protect against glue smells?

Yes, ProDefend filters use activated carbon technology designed to capture and neutralise adhesive odours, making breathing safer and more comfortable.

Can regular dust masks block glue or solvent fumes?

No, standard dust masks do not filter chemical vapours. You need filters specifically rated for organic vapours, like those in ProDefend, for adequate protection.