Best Filters for Timber Sanding: FlowCore Pads & CoreMask Advice

In This Article

- Use P3-rated filter pads for hard/tropical wood sanding, especially indoors.

- Ensure a proper seal every session; facial hair can reduce effectiveness.

- Pair masks like CoreMask with certified pads such as FlowCore for best results.

- Invest in both mask protection and general dust extraction systems.

- Replace filters regularly and store them in dry, sealed environments.

Why Timber Sanding Masks Matter

Understanding the Health Risks of Wood Dust

Timber sanding masks are not just for show—they are a crucial protector against airborne wood particles that arise during woodworking. The fine dust created while sanding timber contains ultra-fine particulates that can be inhaled deeply into the lungs. These particles, especially from hardwoods, are known to cause respiratory issues and diseases if exposure is prolonged. In the UK, the Health and Safety Executive (HSE) clearly outlines the dangers of wood dust, including nasal cancer and occupational asthma. DIY enthusiasts and professional joiners alike often work in confined spaces with insufficient ventilation, which makes the use of high-quality timber sanding masks absolutely essential for minimising exposure.

Timber dust is more than just a lung irritant—it’s a recognised carcinogen, particularly from species like oak and beech. A typical mask does not offer sufficient filtration efficiency; hence, understanding the importance of rated filters like P2 and P3 is vital. The use of masks designed specifically to trap these fine particulates is not just advisable but necessary. The dust also tends to linger in the air even after sanding has stopped, meaning that eruptive exposure can happen with every re-entry into the workshop. Without the correct dust protection, regular sanding may accumulate health impacts over the years. This is why professionals often cite timber sanding masks as a fundamental investment in personal safety.

Choosing the Right Filter Pad

P2 vs P3 Filtration Explained

When choosing timber sanding masks, one must consider the filtration standard, especially between P2 and P3 graded filter pads. P2 filters provide moderate protection and are effective for general sanding work involving softwoods. They can trap about 94% of airborne particles and are suitable for lower-exposure environments. However, P3 filters step up the protection by filtering out up to 99.95% of the fine dust—ideal for hardwoods, MDF, and other ultra-fine particulate-generating tasks.

You might assume that upgrading to a P3 filter is always better. While that’s logically sound from a filtration standpoint, P3s usually feature higher resistance that could hinder breathability if not paired with a well-designed respirator. However, today’s top-tier masks are built to ensure superior air circulation alongside high filtration, mitigating this compromise. Always verify if the mask and pad combo has been tested as a unit and certified to comply with EN 143 or EN 149 regulations, depending on the respirator type. Not all mask-pad pairings are interchangeable, so checking compatibility before use is paramount for achieving the targeted level of protection.

“Always match your filter grade to the timber type and sanding intensity. One size rarely fits all when safety is on the line.”

FlowCore Pads: Fine Dust Champions

Filter Ratings and Lab Testing Review

FlowCore has emerged as a leader in fine dust filtration, specifically designed for high-risk woodworking environments. Their P3-class filter pads undergo rigorous laboratory evaluations to ensure compliance with European safety standards. The internal blend of electrostatically charged fibres captures micron-level debris with impressive longevity, making FlowCore ideal for prolonged indoor use. What sets it apart is its minimal airflow resistance despite its protection rating, providing excellent breathing comfort alongside reliability.

Independent testing shows that FlowCore filters reduce fine dust particles (PM2.5 and below) to almost negligible levels in sealed environments, a significant metric for those sanding timber indoors in small workshops. The filter pads are also engineered with multi-layered materials that resist clogging—a common issue during repetitive or long-duration sanding sessions. Woodworkers have reported consistent airflow over multiple uses without requiring premature replacements. Together with compatible masks, FlowCore becomes an excellent dust filtration solution highly suited to UK-based crafters and hobbyists working with a variety of woods.

Meet CoreMask: Interactive Dust Protection Tech

Features of a Flexible DIY Respirator

CoreMask is a newer entrant in the reusable respirator space, offering smart contouring and filter compatibility aimed specifically at hands-on DIY users. Unlike rigid mask structures, CoreMask uses a flexible elastomeric body that moulds comfortably to most face shapes, ensuring uniform pressure and an effective seal. The adaptability makes it especially useful for glasses wearers, who often struggle with fogging and discomfort with stock-standard respirators.

Beyond comfort, CoreMask excels in ease of filter replacement. Users can swap between FlowCore’s P2 and P3 filters quickly without complex assembly, making it ideal for those switching between low- and high-risk sanding tasks. Additionally, CoreMask includes a low-profile exhalation valve to reduce moisture build-up inside the mask—keeping artisans focused instead of fatigued. For added convenience, the adjustable head harness suits a variety of head sizes, enhancing usability across all demographics of woodworkers. Compatible with eye protection and earmuffs, CoreMask’s design prioritises comprehensive safety without compromise.

Sanding Indoors Safely

Managing Ventilation and Filter Integrity

Sanding timber indoors introduces unique challenges, with ventilation and filter degradation top among them. Closed indoor spaces often intensify fine dust concentration, prolonging exposure even after work ends. Hence, it is essential to pair your timber sanding masks with proper airflow strategies. This includes cross-ventilation using window openings and forced air extraction systems. A ceiling fan or a workshop-specific HEPA air purifier can further help remove lingering particles.

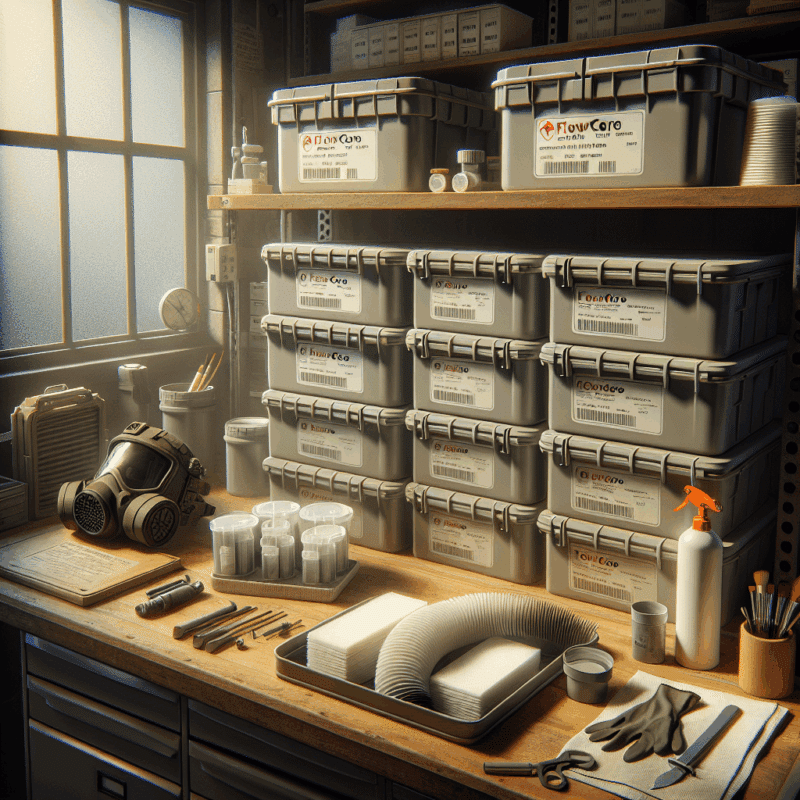

A second important consideration is mask maintenance. Masks left exposed to indoor moisture, such as from damp basements or humid garages, may experience compromised filter integrity. Filters should always be stored in dry, sealed containers and replaced after the manufacturer’s recommended usage period. Use visual inspection methods—discolouration, structural deformation, and airflow resistance changes—as cues to determine filter degradation. Never attempt to “clean” or wash P2 or P3 filters, as this voids their certification. Instead, always keep spare filters on-hand during extensive woodworking projects.

What the Community Thinks

Feedback on CoreMask and FlowCore Usage

Community consensus on timber sanding masks, especially CoreMask paired with FlowCore pads, remains overwhelmingly positive. On UK woodworking forums and YouTube review channels, users have consistently noted the balance between comfort and high-level filtration. One Reddit user noted, “I finally stopped coughing after long sanding sessions when I switched to CoreMask and FlowCore.” Testimonials from cabinetmakers and guitar builders highlight decreased respiratory irritation and ease of extended wear.

Users also appreciate the low maintenance costs. Since both CoreMask and FlowCore filters are reusable or replaceable at reasonable intervals, they offer cost efficiency compared to disposable respirators. Custom-mould fit and secure straps are also praised often. Small workshop owners appreciate the respirator system most for its indoor effectiveness, reporting visibly reduced dust levels even without heavy extractor setups. Online communities regularly compare features and pricing, offering advice to newcomers. It’s clear these products enjoy a reputation for delivering high-quality protection validated by everyday experience.

HEPA vs P3 Filters Debate

Forum Insights and Common Misconceptions

One of the most common confusions within UK DIY circles is the distinction between HEPA filters and P3 filters. Many incorrectly assume that HEPA vacuum filters offer the same respiratory protection as P3 mask filters. In reality, HEPA filters are designed for air purification in devices and not for direct respiratory use. While both target fine particulates, their design criteria, airflow tolerances, and exposure dynamics are vastly different.

Forums like Learn more about Personal protective equipment for woodworking have explored this thoroughly. The bottom line remains: P3 filters are specifically rated for use in respirators, tested under inhalation conditions that mimic actual breathing. HEPA filters, although effective in air purifiers, don’t replicate the seal or consistent airflow control required in a mask. Don’t retrofit HEPA vacuum components for respirator use. Trust only products certified under EN 143 or EN 149 for human inhalation protection. For expert advice, always review updated industry-specific guidelines provided at HEPA filters and health during timber sanding.

Mask Fit and Seal Tips

How to Achieve Leak-Proof Safety

Even the most advanced filter system won’t protect you if the mask fit is inadequate. Ensuring a proper facial seal with your timber sanding masks is essential. Start by conducting a seal check every time you wear the mask—cover the filters and exhale gently. If air escapes from the edges, adjust the straps or reposition the mask until the leak stops. A good seal leaves the mask slightly collapsing inward during inhalation, proving air is passing through the filters.

Facial hair, especially beards, can significantly reduce the effectiveness of any mask. For those unwilling to shave, investing in a powered air-purifying respirator (PAPR) might be worthwhile. Padding can also wear out over time, so periodically checking the elasticity and seal condition of your mask ensures consistent protection. It’s also advised to consult Read a related article for a sizing chart or sealing videos that ensure a near-perfect fit every single time.

Workshops and Dust Control Strategy

Dust Filtration in Small UK Indoors

Many UK workshops are converted sheds, garages, or attics—spaces where dust lingers longer due to poor natural airflow. In such setups, advanced mask protection is only one piece of a larger dust control strategy. Incorporating dust collection systems at the source—such as connected vacuum sanding units—is a significant upgrade. Using dust-trapping mats and rubber floor seals can also reduce airborne recirculation. Daily vacuuming using HEPA-certified shop vacs helps to maintain clean working environments.

Drywall seams, old carpets, and fabric insulation can trap and later re-release particles if not maintained. Therefore, optimising your workspace to combat airborne wood particulates includes strategic masking, mechanical extraction, and good housekeeping. Combining a FlowCore-enhanced mask with clever workshop planning ensures reduced health risks even when professionally installed dust extraction is outside your budget.

Where to Get the Right Filters

UK Availability and Trusted Retailers

For British woodworkers, sourcing reliable filter pads and masks is easier than ever. Timber sanding masks from recognised brands like CoreMask paired with FlowCore filters are stocked at specialist retailers and available via trusted online platforms. Look for suppliers who list certification numbers and provide datasheets for their filtration products. UK-based outlets that distribute HSE-compliant respirators include Discover AI-driven UK website growth, as well as dedicated woodworking and safety equipment shops.

Always avoid bulk unbranded imports unless they include verifiable filtration ratings. Generics may look tempting price-wise but often lack the protective credentials required for health-grade safety. Keep a lookout for seasonal discounts provided by legitimate PPE stockists, and remember—long-term investment in respiratory protection pays off every time you start the sander.

Conclusion: Your Next Step in Wood Dust Safety

Protecting your lungs is non-negotiable, especially for those frequently exposed to timber dust. Choosing top-tier timber sanding masks like CoreMask with FlowCore filter pads offers a sophisticated, proven solution. By understanding the distinction between filter classes, prioritising indoor safety planning, and securing a proper fit, you significantly reduce your risk of long-term respiratory issues. Take proactive steps now—whether you’re sanding indoors or in workshops—because safety gear is far more than equipment; it’s a long-term investment in your well-being.

Great guide on best-timber-sanding-mask-filter-guide – Community Feedback

What filter rating is best for timber sanding?

For timber sanding, use P2 or P3 (FFP2/FFP3) filters. These are designed to filter fine wood dust, providing high protection for most sanding projects.

Can FlowCore pads be used with CoreMask-interactive for woodwork?

Yes, FlowCore pads are compatible with Torxup CoreMask-interactive systems, providing efficient filtration suitable for timber sanding tasks.

Do I need a particulate or chemical filter for sanding wood?

A particulate filter is most important for sanding timber, as it traps hazardous dust. Use a carbon filter only if working with treated or painted wood emitting fumes.